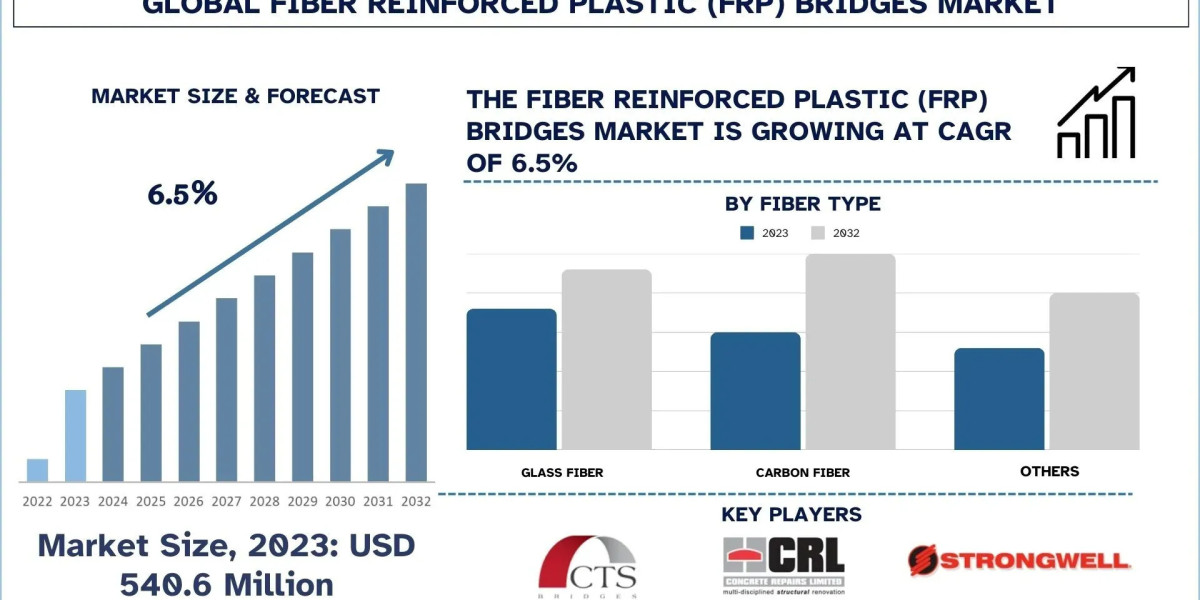

According to the UnivDatos, increasing infrastructure investments, demand for lightweight and corrosion-resistant materials, and the need for cost-effective, durable solutions drive the Fiber Reinforced Plastic (FRP) bridges market. As per their “Fiber Reinforced Plastic (FRP) Bridges Market” report, the global market was valued at USD 540.6 million in 2023, growing at a CAGR of about 6.5% during the forecast period from 2024 - 2032 to reach USD million by 2032.

FRP bridges are advanced composite structures where high-strength fibers such as glass, carbon fibers, aramid, or basalt fibers are used in combination with a polymer resin matrix. The exceptional durability and outstanding resistance to corrosion together with a favorable strength-to-weight ratio make these bridges suitable for all kinds of traffic including vehicles and foot traffic. FRP bridges outperform steel and concrete bridges because they resist rusting and need small maintenance while retaining superior longevity, especially when exposed to harsh coastal conditions or severe temperature zones. These materials are of less weight which enhances installation speed while decreasing the final project costs. FRP bridges serve as important structures in accelerated bridge construction (ABC) operations, in the rehabilitation of outdated infrastructure, and in the sites that cannot support heavy construction materials. Rising sustainable infrastructure spending and composite technology development have made FRP bridges the optimal solution for present-day low-maintenance budget-friendly bridge systems.

1. Increased use of FRP materials

The bridge construction market is widely adopting FRP materials because of their several advantages over traditional materials such as steel and concrete. The lightweight property of FRP materials enables quicker and less expensive bridge construction as it cuts down both labor costs and delivery expenses. This material provides exceptional strength-to-weight performance and resistance against corrosion which makes it perfect for difficult environments such as coastal areas and heavily contaminated industrial zones where normal materials show fast decay. Government entities as well as infrastructure developers across the world are embracing FRP due to its sustainable advantages such as reduced maintenance expenses and improved longevity. Moreover, FRP materials are gaining popularity due to sustainability programs and environmental controls that demonstrate that they can reduce carbon emissions while supporting green building standards, leading to their huge growth.

2. Dominance of Polyester Resin

The Fiber Reinforced Plastic (FRP) bridge market depends primarily on polyester resin because it provides durable performance, affordable cost, as well as adaptable mechanical characteristics. The construction of FRP bridges widely uses polyester resin as it withstands moisture and chemicals efficiently and resists environmental breakdown which enables this material to function optimally in harsh coastal and industrial settings. The high affordability of polyester resin compared to epoxy and vinyl ester resins makes it the preferred material for the infrastructure construction sector due to its cost-efficiency requirements. The combination of polyester resin with glass fiber results in excellent fiber reinforcement which promotes reliability and prolonged service duration. The ongoing improvement of resin formulations has increased its mechanical strength, as well as fire-resistance properties which makes it perfect for bridge construction applications. The ongoing global infrastructure development primarily in low-cost regions will sustain high demands for polyester resin-based FRP bridge, which will further strengthen its market leadership during the forecasted period.

Access sample report (including graphs, charts, and figures) - https://univdatos.com/reports/fiber-reinforced-plastic-bridges-market?popup=report-enquiry

3. Growing adoption of Prefabricated FRP Bridge Components

Prefabricated bridge components are the components of the bridge, which are ready to use directly at the construction site. These are increasingly preferred by the construction industry due to their fast infrastructure delivery. These help in the overall cost reduction and are comparatively easy to install directly on the construction site. The manufacturing of prefabricated FRP bridge components takes place in a controlled environment where high-quality accuracy is ensured before their final installation at the construction sites. The construction period is significantly reduced by following this approach which makes FRP bridges suitable for emergency repair needs and fast infrastructure creation projects. These potential benefits of prefabricated bridge components are driving the growth of the FRP bridge market in the forecasted period.

Conclusion

The market for Fiber Reinforced Plastic (FRP) bridges is set to grow because of ongoing trend situations like the increased use of FRP, and the dominance of polyester resin as well as growing adoption of prefabricated FRP bridge components. These trends are developing the Fiber Reinforced Plastic (FRP) bridges market globally as well as influencing the development of innovative materials that can promote sustainability.

Contact Us:

Email - contact@univdatos.com

Website - www.univdatos.com