Finding a reliable Expansion Vessel Manufacturer in Tamil Nadu matters for system safety and uptime. This article explains how to evaluate local suppliers, compare materials and certifications, and choose a maker that meets industrial standards.

TL;DR

Look for ASME Section VIII compliance, material traceability, and proven testing. Stainless and carbon steel have different trade-offs for pressure and corrosion. Custom designs and documented QA shorten commissioning risk.

Manufacturer Selection & Credentials

Start by confirming certifications and past project experience with an expansion vessel manufacturer in Dubai.

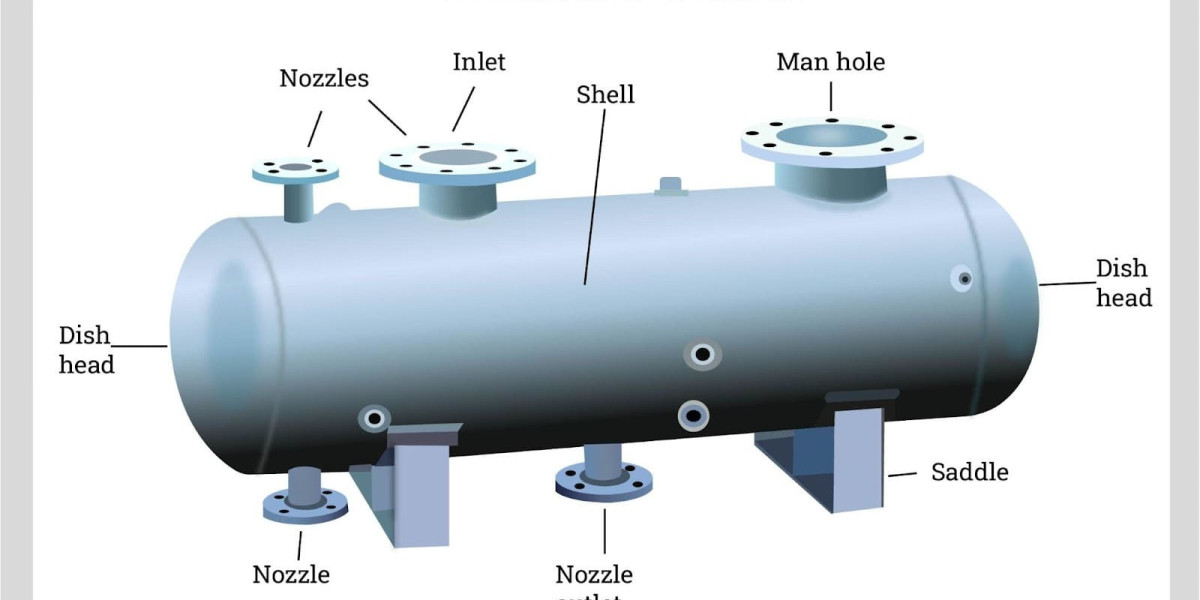

Definition: an expansion vessel is a pressure-rated tank that absorbs volume changes in closed systems. Seek suppliers with ASME Section VIII Division 1 approval and visible quality systems. You can verify certificates by requesting copies of weld procedure qualifications, material certificates, and the ASME authorization.

Example: many Tamil Nadu fabricators supply industrial vessels but only a subset maintain ASME stamping. *Request documented evidence before purchase.* For a supplier profile and product details, review Precision Storage Vessels’ expansion tanks here. For standard references, consult the ASME site: ASME.

Technical Specifications & Materials

Choose materials and specs based on pressure, temperature, and fluid chemistry.

Definition: stainless steel offers corrosion resistance while carbon steel delivers cost-effective strength. Typical pressure ratings range from 1 bar to 50 bar or higher for custom builds.

Stainless steel: best for corrosive fluids and higher temperatures.

Carbon steel: economical, ideal when corrosion control exists.

Bladder options: butyl, EPDM, or replaceable heavy-duty membranes affect life span.

Expert tip: specify welded joint class and non-destructive testing (NDT) level up front to avoid surprises during QA.

Custom Solutions & Applications

Many manufacturers in Tamil Nadu offer custom designs for industry-specific needs.

Definition: custom expansion vessels adapt shell thickness, nozzle layout, supports, and surface treatments to match process requirements. Vendors can produce vessels for HVAC, chemical reactors, steam systems, and oil & gas skid packages.

Example: a petrochemical plant will need higher-grade metallurgy and additional surface coatings. Precision Storage Vessels lists tailored options and bladder types on their product page for international projects (product details).

Pricing & Delivery

Price depends on materials, testing level, and customization scope.

Key cost drivers include plate thickness, stainless alloy grade, NDT methods, and ASME stamping fees. Lead times vary: standard stocked units ship in weeks; ASME-certified custom vessels often take 8–12 weeks.

Tip: plan procurement timelines and specify export packing if you need international shipping from Tamil Nadu ports.

Certifications & Testing

Certified testing proves safety and long-term reliability.

Definition: testing confirms structural integrity through both destructive and non-destructive methods. Common tests: hydrostatic pressure testing, radiography, ultrasonic testing, and pressure relief device checks.

Essential testing checklist:

ASME Section VIII conformity and stamping

Material Test Certificates (MTCs) to EN/ASTM standards

Hydrostatic test at specified test pressure

Radiographic or ultrasonic weld inspection

Painting/coating and corrosion protection records

Factory acceptance test (FAT) documentation

How to Choose: Selection Checklist

Follow a short checklist to reduce procurement risk.

Request ASME and MTC copies before PO.

Ask for recent FAT and client references in Tamil Nadu or similar industries.

Specify NDT level and welding procedure qualification (WPQ/WPS).

Confirm lead time, packing, and export capability.

Include spare bladders and maintenance parts in the contract.

Industry Applications

Expansion vessels protect systems across multiple sectors.

HVAC: Control thermal expansion in heating and chilled-water loops. *Common and highly standardized.*

Oil & Gas: Manage pressure surges and storage of pressurized fluids in processing skids.

Chemical: Handle reactive fluids requiring corrosion-resistant alloys and strict traceability.

Power Generation: Control steam condensate and prevent water hammer in turbine systems.

Summary

Choosing the right Expansion Vessel Manufacturer in Tamil Nadu means checking ASME conformity, matching materials to process conditions, and demanding clear testing records. Using the checklist above and verifying certificates will reduce risk and shorten commissioning time. For detailed product specs and factory capabilities, review Precision Storage Vessels’ expansion tanks and test reports.

FAQs

Which expansion vessel manufacturers in Tamil Nadu have ASME certification?

Several fabricators in Tamil Nadu hold ASME Section VIII credentials, but always verify current ASME stamps and project references before awarding a contract.

What certifications should I look for in an expansion vessel supplier?

Look for ASME Section VIII stamping, Material Test Certificates, welding procedure qualifications, and documented NDT records.

How do I verify if a manufacturer meets international pressure vessel standards?

Request scanned copies of ASME authorization, MTCs, and third-party inspection reports; confirm details with the certifying body when needed.

What materials are best for high-pressure expansion vessels?

Stainless steel alloys like 304/316 or higher grades suit corrosive, high-temperature services; carbon steel works for non-corrosive, lower-cost needs.

Can manufacturers provide custom designs for my industry?

Yes. Most experienced vendors offer custom shell geometry, nozzle arrangements, and special coatings to meet industry specs.

How long does it take to manufacture custom expansion vessels?

Standard custom ASME vessels typically require 8–12 weeks; complex metallurgy or additional testing can extend lead times.