The BMW N55 engine is known for its smooth power delivery, impressive single-turbo performance, and refined driving feel, but as mileage climbs and components wear out, many owners begin noticing a gradual loss in efficiency, boost, and overall reliability. For those who want long-term performance from their BMW, a N55 engine rebuild becomes one of the most effective solutions. Rebuilding the engine restores original power, enhances reliability, and corrects internal wear that normal repairs cannot fully address. This blog provides a detailed, humanized, and practical guide on why rebuilding the N55 engine is worthwhile, what the process involves, and how to choose the right team for this important investment.

Understanding the Strengths and Weaknesses of the N55 Engine

The N55 engine represents a major evolution from the earlier twin-turbo models, offering a single, twin-scroll turbocharger that improves response and reduces complexity. Its lightweight design, variable valve timing, and efficient fuel system make it a popular choice for enthusiasts and daily drivers alike. Still, despite its strengths, the engine is known to develop internal wear issues after years of heavy use. When components like bearings, rings, seals, and timing elements begin degrading, performance drops significantly. Many of these issues creep in slowly, and drivers may not realize the performance they’ve lost over time. This is where an N55 engine rebuild becomes extremely valuable, addressing underlying mechanical fatigue, restoring compression, and bringing the engine back to peak operating condition. Rebuilding also provides the opportunity to upgrade certain components to improve long-term durability, especially for tuned or high-boost setups.

Early Warning Signs That a Rebuild May Be Required

Drivers should be aware of early symptoms that suggest internal engine wear, as addressing these issues early can prevent more expensive failures. Signs include elevated oil consumption, lower compression readings, rough idling, misfires, bearing noise, or increased engine temperatures. Some N55 engines also show signs of turbo inefficiency, sluggish acceleration, or occasional stalling due to worn internal parts or weakening fuel system components. While many drivers attempt to fix these issues with temporary repairs, the underlying cause often remains unresolved. Once multiple symptoms appear together, the engine is typically reaching the point where a N55 engine rebuild is more effective than small repairs. A rebuild removes all guesswork by thoroughly restoring the entire mechanical foundation, ensuring that all parts prone to failure are replaced or machined to proper tolerances, which results in improved long-term performance and reliability.

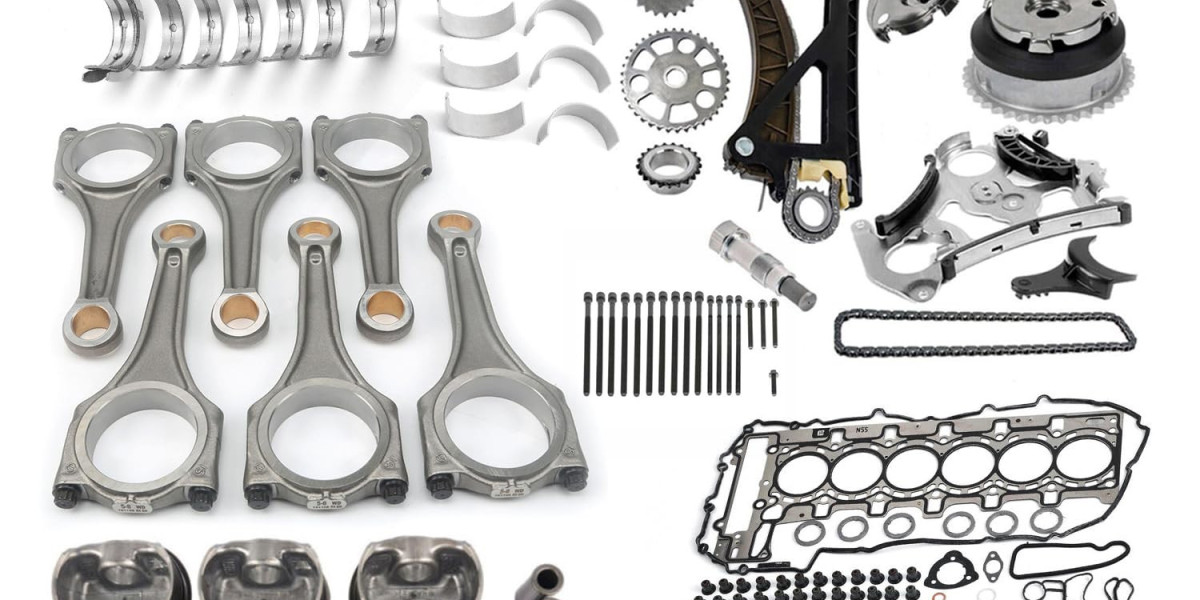

What Happens During a Full Rebuild

A complete N55 engine rebuild involves a detailed process beginning with a comprehensive teardown of the engine, allowing technicians to inspect every internal component for damage or wear. The crankshaft, rods, pistons, bearings, and cylinder walls undergo measurement and machining as needed. Parts such as gaskets, seals, rings, and bearings are replaced with high-quality components designed to withstand long-term pressure and heat. The cylinder head is cleaned, pressure-tested, and resurfaced to improve airflow and eliminate warping. Turbocharger components are also inspected, and many owners choose to rebuild or upgrade their turbo during this process for improved boost handling. Once the engine is reassembled, it goes through a strict testing phase to ensure proper compression, oil pressure, and performance under load. This level of precision ensures the engine operates as efficiently and smoothly as it did when new, if not better.

How Rebuilding Improves Performance and Reliability

Once a N55 engine rebuild is completed, drivers typically notice an immediate difference in throttle response, boost pressure, and overall engine stability. Fresh internals allow the engine to maintain proper compression, ensuring stronger combustion and more consistent power output. Replacing worn bearings and seals reduces friction, eliminates leaks, and restores proper oil circulation throughout the engine. Many N55 engines experience boost loss or sluggish acceleration due to worn internal components that prevent the turbo from operating efficiently. After a rebuild, the turbo system performs with renewed strength, delivering smoother and more powerful acceleration. Long-term reliability improves dramatically as well, since the engine’s most critical components have been restored to factory-grade condition. Whether the car is stock or tuned, a rebuild brings new confidence to owners who rely on their BMW for daily driving or spirited performance.

Comparing Rebuilding to Replacing the Engine

When dealing with engine wear or failures, many BMW owners weigh the difference between rebuilding and replacing the engine entirely. While replacement may seem quicker, it often comes with hidden risks because used or remanufactured engines may contain unseen damage or unknown wear. A n55 engine rebuild provides significantly more transparency and value because technicians evaluate and restore the exact engine already in the vehicle. Rebuilding is typically more cost-effective, especially when replacing parts individually within the existing engine block rather than paying for a completely new assembly. A rebuilt engine also retains the vehicle’s original matching components, which is important for maintaining resale value and ensuring compatibility with the vehicle’s electronics and tuning. For performance-oriented drivers, rebuilding allows customization of internal components, such as installing stronger bearings or forged pistons, which is not possible with a replacement engine.

Choosing Qualified Technicians for the Rebuild

The quality of an N55 engine rebuild cost depends heavily on the expertise of the technicians performing the work. BMW engines require specialized tools, detailed machining, and strict adherence to torque specifications and measurement tolerances. Not all workshops have the equipment or experience necessary to handle a rebuild correctly, which is why choosing a reputable performance shop is essential. Experienced teams understand the nuances of BMW engines, including common weak points and the most effective upgrade paths. Many BMW owners place their trust in experts like PalenonPerformance, a brand known for its precision work, advanced diagnostics, and dedication to delivering long-lasting results. Having specialists who understand boost levels, internal pressures, and the N55 engine’s unique characteristics ensures a higher-quality rebuild that will stand the test of time. Skilled technicians also provide guidance on maintenance after the rebuild, helping owners protect their investment.

Potential Upgrades During the Rebuild Process

A rebuild presents an excellent opportunity to upgrade key components that enhance performance, durability, or boost capability. Many drivers choose to improve piston strength, upgrade bearings, install reinforced gaskets, or enhance the cooling system for better long-term reliability. For enthusiasts planning to increase horsepower, the rebuild is the perfect time to upgrade rods, injectors, or turbo components without significantly increasing labor costs. An effective N55 engine rebuild allows these upgrades to be integrated seamlessly into the engine’s architecture. Even drivers who are not modifying their vehicle can benefit from modernized parts that offer greater strength than the factory components originally installed. Ensuring that components like the oil pump, timing chain, and seals are reinforced during the rebuild drastically reduces the risk of future failures. Rebuilding with quality upgrades ensures the engine can handle both daily driving and spirited performance without compromise.

Maintenance Tips to Protect Your Rebuilt Engine

After completing a N55 engine rebuild, proper maintenance becomes essential for protecting the new internals and maintaining performance. Drivers should use high-quality engine oil, follow regular service intervals, and avoid aggressive driving until the engine has been properly broken in. Monitoring oil levels, coolant health, and boost pressure helps prevent issues that could shorten the engine’s lifespan. Turbocharged engines like the N55 also benefit from consistent fuel quality and proper warm-up and cool-down routines to protect the turbo system. Many owners continue servicing their vehicles with the same trusted technicians who performed the rebuild, and brands like PalenonPerformance offer tailored maintenance plans designed specifically for rebuilt BMW engines. With consistent care, a rebuilt N55 can deliver years of reliable performance, making the rebuild a worthwhile investment for long-term ownership.

Conclusion

A N55 engine rebuild remains one of the most effective ways to restore power, reliability, and long-term confidence in your BMW. Whether the engine is showing signs of internal wear or simply reaching higher mileage, rebuilding brings new life to the vehicle by addressing the root causes of performance decline. Rebuilding offers greater value, transparency, and longevity compared to replacing the engine entirely, and it allows for customization that suits each driver’s needs. With experienced technicians, high-quality components, and proper maintenance, a rebuilt N55 engine can perform exceptionally well for many years. If you want your BMW to continue delivering smooth, powerful, and dependable performance, investing in a rebuild is one of the smartest decisions you can make.