Harvesting remains one of the most time-sensitive and capital-intensive stages of crop production. As farms scale and operating margins tighten, agricultural machinery decisions increasingly influence not only productivity but also risk management, labor planning, and long-term sustainability. Within this landscape, combine harvesters represent a convergence of engineering philosophy, agronomic requirements, and operational strategy.

For professionals and business owners, the question is rarely whether to mechanize harvesting but how to align specific combine technologies and brand approaches with field conditions, crop profiles, and operational scale. Rotary, hybrid, and conventional systems each address different challenges, and manufacturers have adopted distinct interpretations of these designs.

Combine Harvesters as Core Industrial Equipment

Modern combine harvesters integrate cutting, threshing, separation, and cleaning into a single coordinated workflow. This consolidation has transformed harvesting into a precision-driven operation, where throughput, grain quality, and residue management must be balanced simultaneously.

From an industrial equipment perspective, combine harvesters now function as:

High-capacity mechanical systems

Mobile data collection platforms

Key coordination points between field, transport, and storage

Understanding how specific brand technology combinations perform within this system is essential for informed machinery planning.

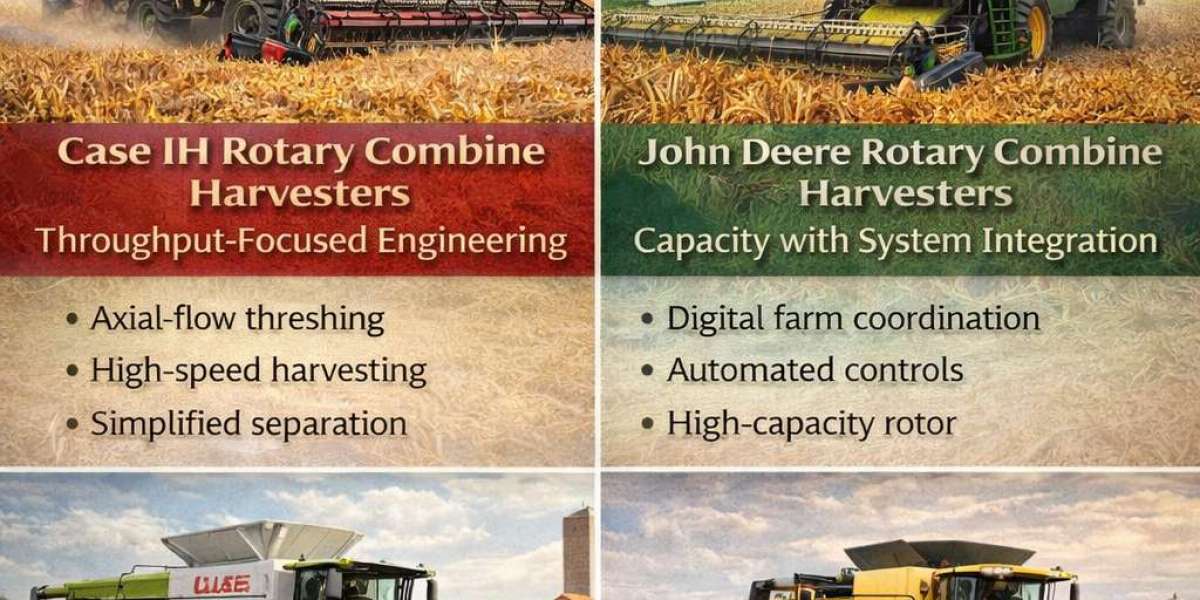

Case IH Rotary Combine Harvesters: Throughput-Focused Engineering

Rotary combine systems have become closely associated with Case IH’s engineering philosophy. By emphasizing axial-flow threshing and separation, Case IH designs prioritize consistent crop movement and simplified mechanical layouts.

Operational Characteristics

Single-rotor design for continuous material flow

Strong performance in high-yield and high-moisture crops

Emphasis on reducing grain damage through controlled separation

These machines are commonly selected for large-acreage operations where harvesting speed and reliability directly affect profitability. An overview of Case Ih Rotary Combine Harvesters illustrates how this approach has remained central to the brand’s combine strategy over time.

John Deere Rotary Combine Harvesters: Capacity with System Integration

John Deere’s rotary combine harvesters reflect a broader system-level view of agricultural machinery. While also focused on high throughput, Deere integrates rotary harvesting within a wider ecosystem of equipment, data, and operational workflows.

Key Design Priorities

High-capacity rotary threshing systems

Operator-centric controls and automation support

Compatibility with digital farm management platforms

For many professional operations, rotary systems from John Deere are valued not only for harvesting efficiency but also for their role in yield analysis and decision support. A structured look at John Deere Rotary Combine Harvesters shows how rotary technology is positioned within a broader machinery portfolio rather than as a standalone solution.

Claas Hybrid Combine Harvesters: Bridging Throughput and Precision

Hybrid combine harvesters emerged to address the trade-offs between rotary and conventional systems. Claas has been particularly influential in refining this approach, combining rotary threshing with straw walker separation.

Where Hybrid Systems Add Value

Balanced performance across variable crop conditions

Improved straw quality compared to full rotary designs

Flexibility for mixed crop rotations

Claas hybrid combines are often used in regions where crop diversity and residue management requirements demand adaptability. An overview of Claas Hybrid Combine Harvesters highlights how hybrid designs reflect the brand’s emphasis on crop-specific engineering rather than maximum capacity alone.

Case IH Conventional Combine Harvesters: Control and Crop Sensitivity

While rotary systems dominate large-scale harvesting, conventional combines remain relevant for operations prioritizing precision and crop handling. Case IH continues to support conventional designs alongside its rotary lineup.

Advantages of Conventional Systems

Precise threshing for delicate or specialty crops

Predictable residue handling through straw walkers

Mechanical simplicity relative to high-capacity rotary systems

In certain agronomic contexts, conventional machines provide greater control over threshing intensity and straw quality. The continued availability of Case Ih Conventional Combine Harvesters reflects the reality that harvesting efficiency is not defined by throughput alone.

New Holland Conventional Combine Harvesters: Practical Versatility

New Holland has historically maintained a strong presence in conventional combine harvester design, particularly for small to mid-scale professional operations.

Design Focus

Reliable threshing performance across diverse crops

Straightforward mechanical layouts

Suitability for operations with varied harvesting schedules

Conventional combines from New Holland are often chosen for their balance of performance and operational familiarity. A technical overview of New Holland Conventional Combine Harvesters illustrates how conventional technology continues to serve a wide range of professional farming systems.

Combine Harvesters in the Precision Agriculture Era

As harvesting equipment becomes more digitally integrated, combine harvesters increasingly act as data hubs within the agricultural machinery ecosystem. Yield mapping, loss monitoring, and machine diagnostics now influence post-harvest decisions as much as mechanical performance.

This shift reinforces the importance of understanding not just machine capacity, but how brand-specific technologies fit into broader operational systems.

For business owners and agricultural professionals, informed machinery decisions are grounded in operational fit, not marketing narratives.

Conclusion: Informed Choices in a Complex Machinery Landscape

The diversity of combine harvester technologies reflects the diversity of modern agriculture itself. Case IH, John Deere, Claas, and New Holland each represent different responses to the same challenge: harvesting efficiently under increasingly complex conditions.

By evaluating brand–technology combinations through an operational lens, professionals can align agricultural machinery investments with long-term productivity, resilience, and sustainability goals without relying on assumptions or trend-driven decisions.