Modern agriculture operates at the intersection of efficiency, scale, and precision. As farms expand and crop cycles tighten, agricultural machinery has become central to how professionals manage productivity, labor, and operational risk. Among all equipment categories, combine harvesters stand out as one of the most technically complex and economically significant investments on a farm.

Beyond their mechanical role, combine harvesters reflect broader trends in agriculture equipment: increasing specialization, integration with digital systems, and brand-driven engineering philosophies. Understanding how leading manufacturers approach combine harvester design offers valuable insight for farm owners, agribusiness leaders, and equipment managers making long-term decisions.

The Strategic Role of Combine Harvesters in Modern Agriculture

Combine harvesters consolidate multiple harvesting operations cutting, threshing, and cleaning into a single, coordinated process. This integration reduces harvest windows, limits crop loss, and helps operations respond to increasingly unpredictable weather patterns.

As agricultural systems have industrialized, combine harvesters have evolved into highly specialized forms of industrial equipment. Differences between machines are no longer limited to size or horsepower; they extend to crop adaptability, automation readiness, residue management, and data capture capabilities.

To navigate this complexity, professionals increasingly rely on structured, neutral reference platforms such as AllMachines, which organize agricultural machinery by category, function, and manufacturer without framing equipment as products to be sold. This type of information-first approach supports better-informed operational planning.

Understanding Combine Harvesters as a Category

From a systems perspective, combine harvesters are not a single machine type but a family of designs optimized for different crops, scales, and regions. Their classification typically considers:

Threshing and separation method

Crop throughput capacity

Field conditions and residue handling

Compatibility with precision agriculture tools

A consolidated view of Combine Harvesters helps illustrate how manufacturers position their machines within this broader agricultural equipment landscape.

What differentiates leading brands is how they balance performance, reliability, and adaptability within these constraints.

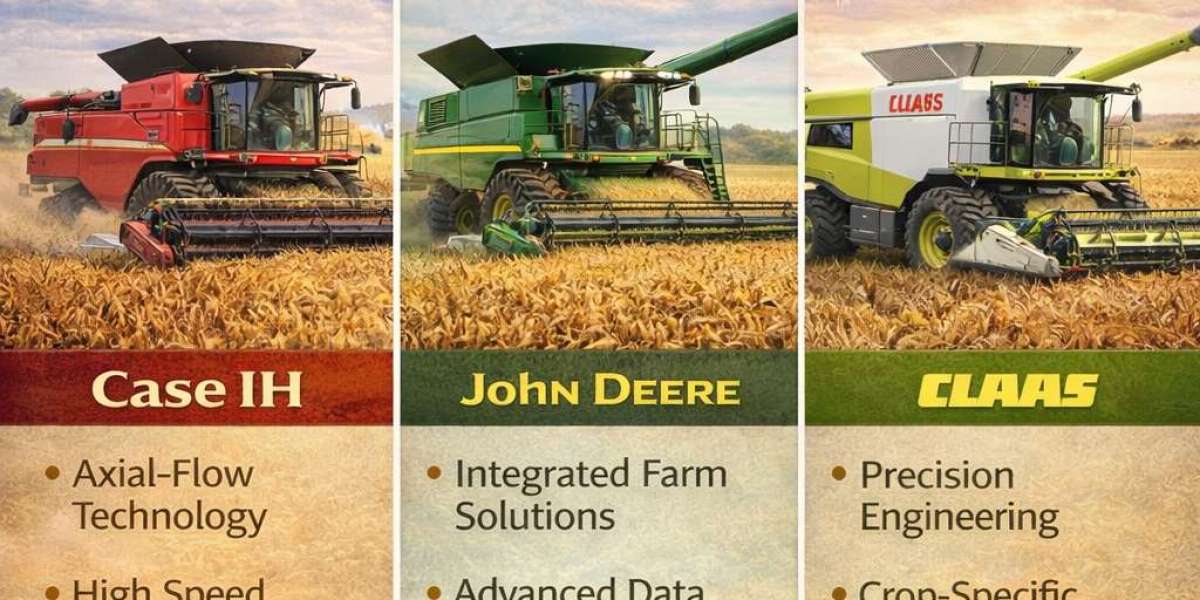

Case IH Combine Harvesters: Engineering for Throughput and Consistency

Case IH has long emphasized axial-flow technology, shaping its approach to combine harvester design around consistent crop movement and simplified separation mechanics.

Core Design Philosophy

Single-rotor threshing systems designed for uniform crop flow

Strong performance in high-yield and high-moisture conditions

Focus on minimizing grain damage while maintaining throughput

Case IH machines are often associated with large-scale grain operations where harvesting speed and consistency directly affect profitability. Their engineering choices reflect an emphasis on reducing mechanical complexity while maintaining capacity.

A structured overview of Case Ih Combine Harvesters highlights how this brand has built a distinct identity around axial-flow harvesting systems rather than offering multiple competing designs.

John Deere Combine Harvesters: Integration and System-Level Thinking

John Deere’s approach to combine harvesters reflects a broader system-level philosophy. Rather than focusing solely on the harvesting mechanism, Deere integrates into a wider ecosystem of agriculture equipment, data platforms, and operational workflows.

Key Characteristics

Multiple threshing and separation configurations

Strong emphasis on operator interface and machine intelligence

Integration with farm management and yield-mapping systems

For many professional operations, John Deere combines are valued not just as harvesting machines but as data-generating assets. Their ability to feed information into planning, logistics, and input optimization workflows is a defining feature.

An overview of John Deere Combine Harvesters shows how the brand supports diverse farm sizes and crop types through a wide equipment portfolio.

Claas Combine Harvesters: Precision and Crop-Specific Adaptability

Claas, a European manufacturer with a strong global presence, is known for precision engineering and crop-specific optimization. Its combine harvesters are often designed with regional farming practices and specialized crops in mind.

Distinguishing Features

Advanced threshing systems tailored to specific crop types

Strong focus on grain quality and residue management

Design heritage influenced by diverse European farming systems

Claas combines are frequently used in operations where crop variability is high and harvesting precision is critical. Their engineering reflects a balance between mechanical refinement and operational flexibility.

A closer look at Claas Combine Harvesters illustrates how the brand positions itself through specialization rather than scale alone.

Comparing Brand Philosophies Without Brand Bias

While Case IH, John Deere, and Claas are often discussed as competitors, their differences are best understood as variations in engineering philosophy rather than simple performance rankings.

At a strategic level:

Case IH prioritizes simplified, high-throughput harvesting

John Deere emphasizes system integration and digital continuity

Claas focuses on crop-specific precision and adaptability

For farm owners and agribusiness managers, the most relevant question is not which brand is “best,” but which design philosophy aligns with their operational realities.

Combine Harvesters Within the Broader Industrial Equipment Ecosystem

Modern combine harvesters operate as part of a tightly coordinated equipment network that includes:

Tractors and grain carts for logistics

Storage and handling systems for post-harvest processing

Digital platforms for yield analysis and planning

Looking Ahead: Brand Diversity in a Converging Industry

As automation, sensor technology, and sustainability requirements advance, combine harvester designs are gradually converging in certain areas. Yet brand differentiation remains relevant, particularly in how manufacturers prioritize:

Operator experience

Data ownership and interoperability

Adaptability to regional farming systems

For professionals making long-term equipment decisions, staying informed about these distinctions is essential. Neutral, reference-oriented resources and independent research continue to play a critical role in enabling informed, non-promotional evaluation.