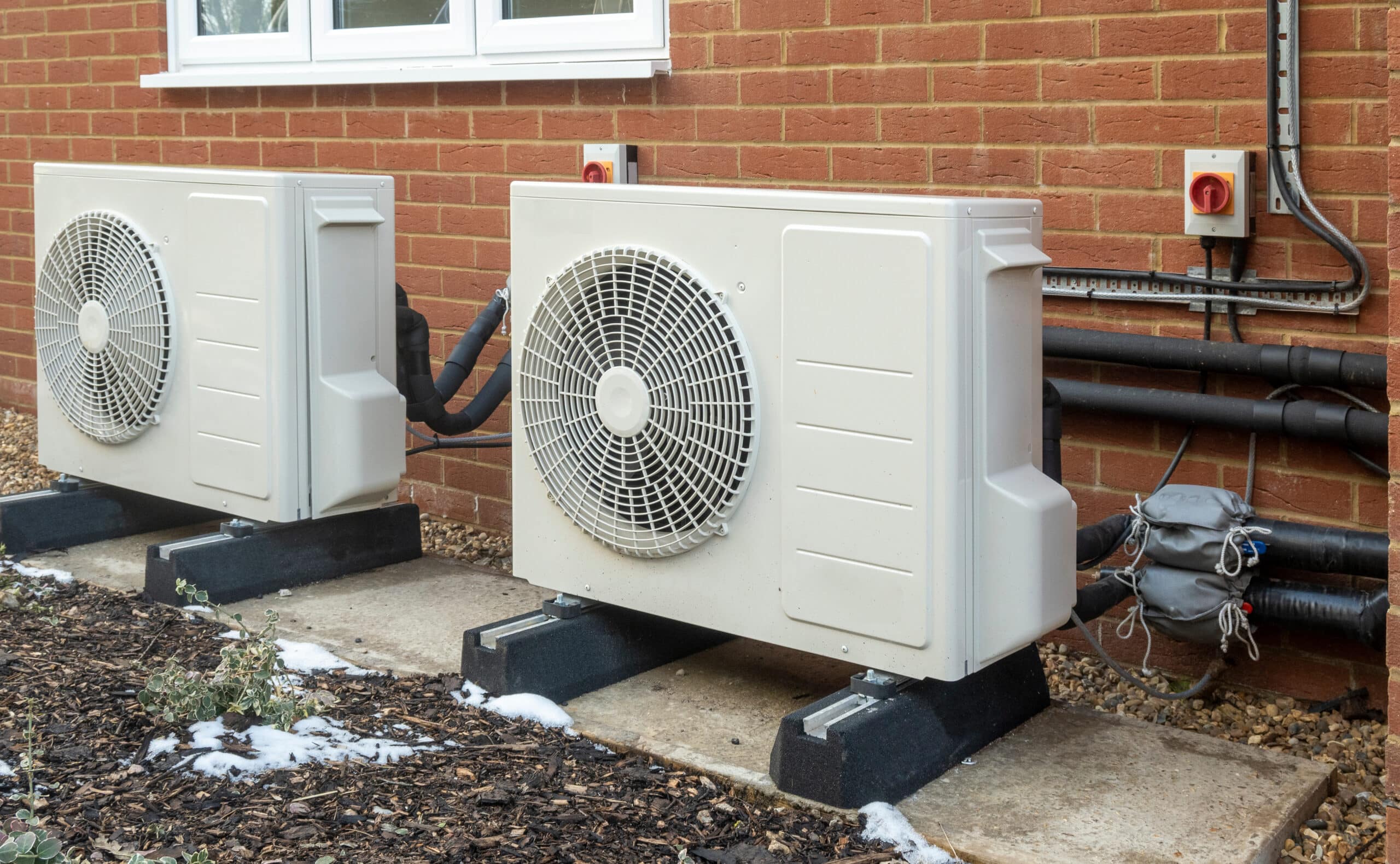

Staying comfortable year-round takes more than flipping a switch; it takes clear choices that balance comfort, safety, and cost. This guide leans into risk-aware decisions so you can avoid costly callbacks and keep systems steady when you need them most. We focus on planning, materials, workflow, risk checks, and long-term care, because each piece shapes results for air conditioning and heating in real homes and small commercial spaces. Use this as a reliable map that reduces guesswork and protects your budget. You’ll get field-tested tips for upgrades, replacements, and tune-ups that fit seasonal needs. We’ll keep it grounded with shop-floor checks, parts selection notes, and coordination tips with tenants or teams. Cost control can pair with quality, if you set scope early, track baselines, and stage work with intention.

Map scope early and align goals with the space

Start with a quick walkthrough to flag load-heavy zones, note breaker capacity, and confirm access points. Place your initial zones on a scaled sketch, HVAC service then label mounting points, condensate runs, and codes to verify. Log ceiling heights and mark where noise or airflow issues could creep in. Define a result for each zone, like "cut evening temperature swing," so choices stay visible. Document existing thermostat locations and sketch wire paths to prevent rework.

Choose a target temperature range and an acceptable humidity level for each space. Capture tenant constraints such as retail peaks so crews minimize disruption. Establish a photo baseline for filters, belts, and line slope to confirm starting condition. With limited access, split work by zone to keep comfort steady. These fundamentals prevent drift.

Select components and inputs that fit usage and building limits

Choose coil and fan pairings that meet load needs without oversizing. For rooftop or closet installs, AC repair verify weight, curb fit, and service access before ordering. Check line set length and match rated charge per spec to avoid performance loss. Pull a submittal package that includes drain fittings so crews don’t stall. For quiet zones, select ECM motors with isolation rails.

Standardize fasteners and gaskets to speed service later. Match filter rating to duty so fans don’t struggle. Choose corrosion-resistant screws for sun and condensate exposure. Label each component for easier future swaps. A thoughtful parts plan saves time today and later.

Stage workflow and schedule around seasonal demand

Build a simple board with zones across the top and tasks down the side. Map the no-noise windows, [HVAC] block delivery times, and sequence tasks so prep finishes before power. Batch minor fixes like drain clamps to keep crews moving. Use a two-bin parts system by zone to limit walk time. Post a daily photo for each area.

Plan buffer for permits without pushing the handoff. Shift noisy work outside customer peaks to protect comfort. Assign roles clearly so leaks, wire pulls, and startups don’t collide. If weather turns extreme, move testing to late hours to keep loads stable. Solid cadence keeps morale up.

Build quality gates that catch issues before they escalate

Set checkpoints: leak test, then diffuser throw. Record readings on a clipboard as each gate clears. During startup, HVAC log coil delta-T, static pressure, and amp draw with ambient conditions. Capture meter screens and attach them to the job log. When a number looks off, stop and fix before moving to the next gate. Tiny fixes avert major downtime.

Run a smoke pencil for duct leaks around seams and plenum joints. Test condensate pumps under load, not just static. Run two full tests after any edit to confirm stability. Log part IDs for future warranty. Good data makes quality visible when teams follow the gates.

Plan care and lifecycle milestones to prevent surprise failures

Set a maintenance cadence tied to usage spikes. For rental or clinic spaces, (ac repair) align visits with tenant patterns so drains get attention without lost hours. Retire at trend lines using trends from amp draw logs. Watch condensate color so crews know when to clean. Small maintenance now avoids big repairs.

When something breaks outside the plan, move fast with Ac repair but keep the same gate steps. Document root causes and decide if drainage should be rerouted. Book the recheck to confirm readings hold after fixes. Train front desk basics like filter slot fits and panel latches. A timeline creates resilience.

Conclusion: A steady process—plan the job, choose solid inputs, stage the flow, verify with gates, and maintain on schedule—keeps comfort and costs in balance. Each step narrows risk, even when timelines are tight or sites stay busy. Adapt these ideas to your space and refine them as your sites evolve. With a quality-first mindset, your systems deliver reliable comfort through every season.