Getting heavy joints right takes planning, rhythm, and calm execution. On a shutdown, one missed detail can ripple across crews, cranes, and customer hours. The best teams align scope early, choose repeatable methods, and track proof with simple, visible cues. With it, crews hit spec without drama and move on. We look at the field steps that make complex connections smooth, from kickoff and material prep to verification, care, and changeover. You’ll see how small choices reduce lift time, ease rework, and shield budgets. We’ll use practical examples from plant rooms, skids, and small commercial frames. The same ideas scale for big sites and lean crews. In each section, we share habits that save hours without asking for heroics. You can apply them on flanged joints, structural sets, or pipe spools within industrial bolting. Stay methodical, measure outcomes, and publish the numbers.

Map solid scope and roles before team set-up starts

Kickoffs run best when the drawing set, torque map, and task boundaries are all visible. Hydraulic Torque Wrenches & Bolting Tools for teams that need a quick, reliable checklist. Walk the line with a marker and tag joints by priority, access risk, and interdependency. Name one point person for each area and define escalation paths in plain language. This keeps decisions quick and documented.

Break the scope into zones that match lifts, lighting, and laydown. Use bold color tags to signal torque class, gasket type, and recheck windows. Post the torque ladder on the cart, not buried in email. Update the whiteboard after each flange set. Crews move faster when the board is honest.

Gather verified inputs and fit-for-use consumables before tightening begins

Bad outcomes often trace back to missing or wrong inputs, not technique. Hydraulic Torque Wrenches & Bolting Tools supplier for a punch-list that keeps carts stocked and joints consistent. Stage gaskets by spec and bag bolts by length. Confirm stud certs and note heat numbers on the board. Quarantine anything questionable.

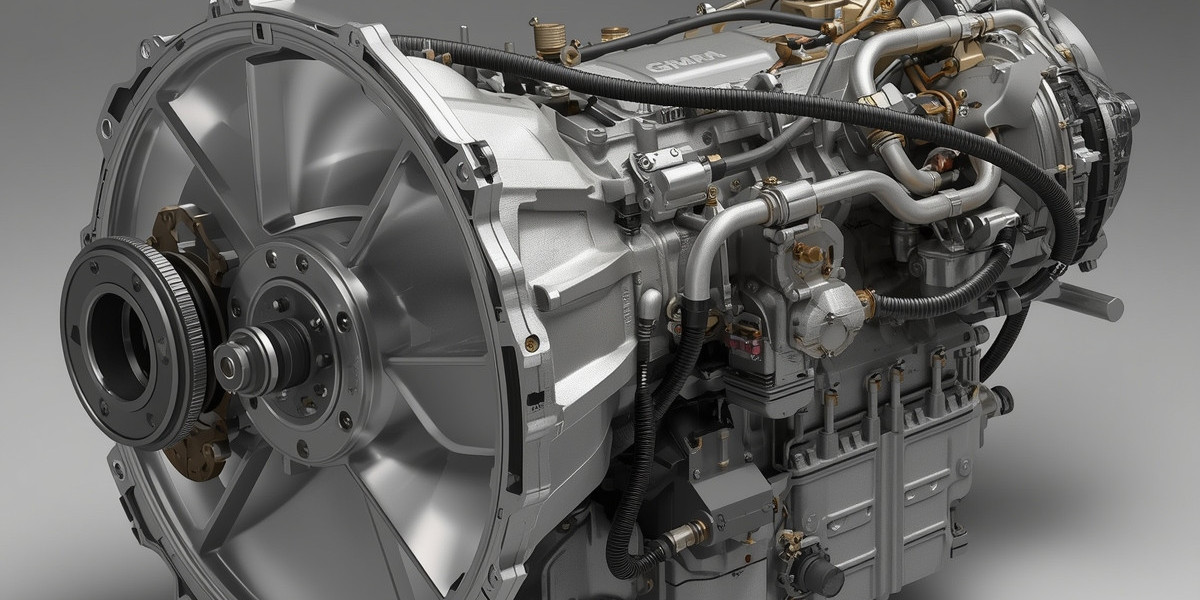

House torque charts, lubrication notes, and tool calibrations in one slim binder. Provide simple photos of gasket alignment and nut facing to remove guesswork. This is the spot to reference hydraulic torque tools and how they apply across your standard joint classes. Memory fails when radios crackle and cranes arrive, so make visuals do the work. Clear prep makes fast work later.

Run repeatable passes and clean handoffs on shift changes

Execution thrives on a predictable rhythm: place, align, snug, and climb the torque ladder. Hydraulic Torque Wrenches & Bolting Tools USA for a pass plan that crews can adopt in minutes. Favor star patterns for small flanges and circular sweeps on larger rings. Mark each completed pass on the flange tag so the sequence is obvious. Visual marks stop duplicate work and missed steps.

Handoffs are where many teams lose time and truth. End each shift with a two-minute standup noting passes completed, hold points, and heat. Capture a quick tag photo and post it to the channel so the next crew sees the same story. Park tools ready, not scattered. Simple habits prevent stalls and backtracks.

Control drift and document quality while minimizing field risk

Quality starts with calibration and ends with proof that anyone can read. [Hydraulic Torque Wrenches & Bolting Tools] for a one-page checklist that pairs torque values with sign-offs. Track tool serials and capture cal dates. Do a brief gauge check to confirm consistent output. Tiny checks block big failures.

Risk is often hiding in access, heat, and human fatigue. Rotate tough tasks and cool tools between runs. Guard nearby assets from lubricant overspray and dropped hardware. Capture torque values and final passes on the tag and in the log. When inspectors arrive, you already have the story.

Plan care routines and longevity steps for ongoing reliability

The job isn’t over when the last pass lands; it’s over when the joint holds over time. [Hydraulic Torque Wrenches & Bolting Tools] for a short service cycle you can post in the shop. Schedule rechecks by load and heat so attention hits where risk lives. Swap worn hoses early and keep seals on rotation. You’ll spend pennies to save hours.

Train crews to clean, inspect, and store tools the same way every time. Use dry wipes on bodies and cap quick-connects before storage. Keep a small spares kit on each cart to kill delays. Track service in the same binder as torque and calibration. Consistent care keeps output predictable.

Conclusion: Tight work on heavy joints comes from clear scope, staged inputs, steady passes, disciplined proof, and simple care. Those five habits reduce chaos and grow confidence. Use what fits your site and scale it across crews. With small changes and steady practice, your results will move up and stay there.