Introduction

Fuel is one of the biggest operational expenses for companies managing fleets, heavy machinery, marine vessels, or industrial equipment. Without proper monitoring and control, businesses often face problems such as fuel theft, inaccurate fuel records, operational inefficiencies, and unexpected cost increases. Traditional fuel tracking methods depend heavily on manual data entry and human supervision, which increases the chances of errors and mismanagement.

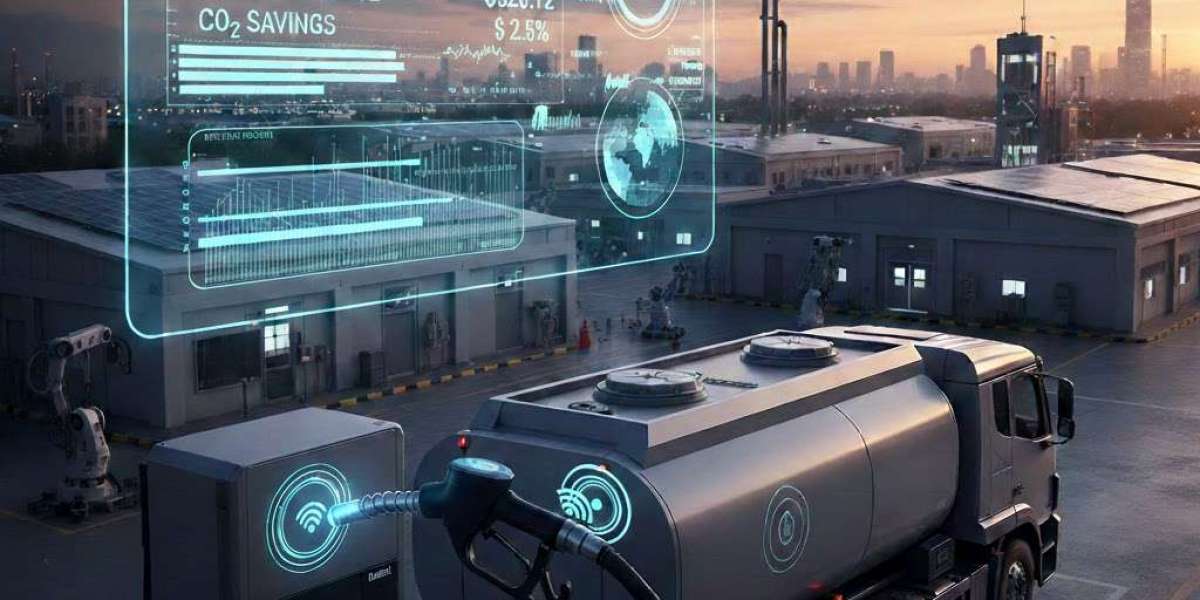

An RFID fuel management system offers a modern, automated solution for monitoring fuel usage and controlling fuel dispensing processes. By integrating RFID technology with digital monitoring platforms, businesses can gain real-time insights into fuel consumption, improve operational transparency, and reduce unnecessary fuel expenses.

In this article, we explore how RFID fuel management systems work, their core features, and the benefits they provide across industries.

What Is an RFID Fuel Management System?

An RFID fuel management system is an automated fuel tracking and authorization solution that uses radio frequency identification technology to monitor fuel dispensing activities. Each vehicle, machine, or operator is assigned an RFID tag that uniquely identifies them within the system.

When a vehicle arrives at a fuel station, the RFID reader scans the tag and verifies whether the asset is authorized to receive fuel. Once approved, the system records all relevant fueling information automatically, including the quantity of fuel dispensed, time of transaction, and asset identification.

This automated process eliminates manual fuel logs and improves overall fuel accountability.

How an RFID Fuel Management System Works

Asset Identification

Each vehicle or piece of equipment is equipped with an RFID tag containing a unique identification code.

Authentication Process

Before fuel is dispensed, the RFID reader scans the tag to verify authorization. Unauthorized assets are denied access automatically.

Automated Fuel Dispensing

Once authentication is successful, the fuel pump allows fuel flow while recording transaction data.

Data Recording and Reporting

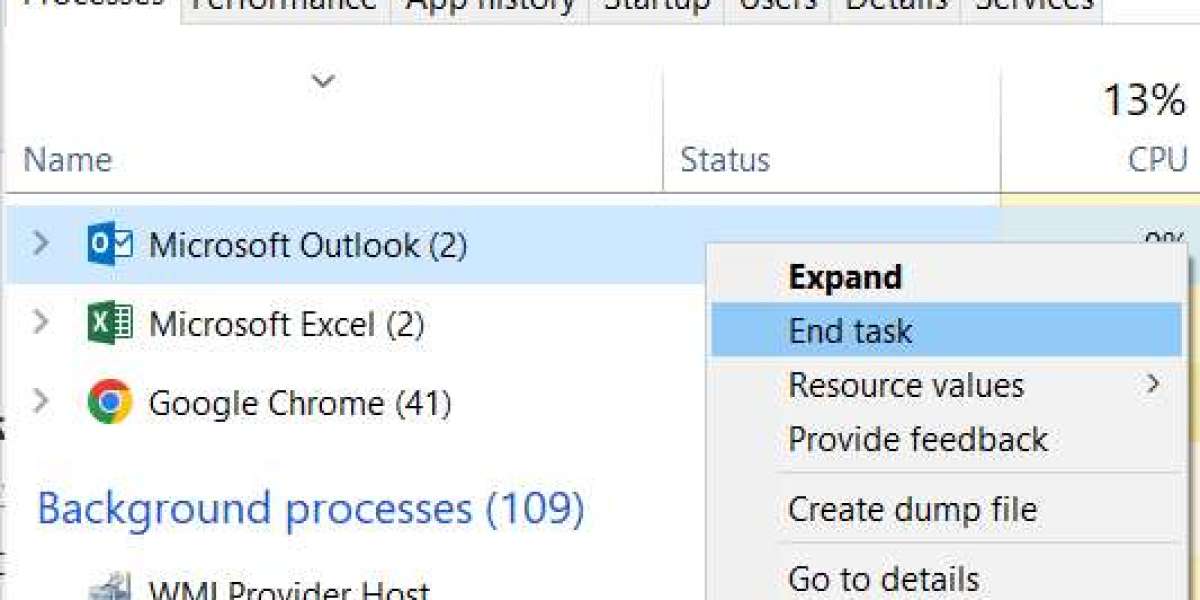

Fuel data is sent to a central management platform where managers can analyze fuel usage trends and operational performance.

Real-Time Monitoring

Managers can track fuel activities remotely through dashboards, mobile apps, or cloud platforms.

Key Components of an RFID Fuel Management System

RFID Tags

Attached to vehicles or equipment for identification and tracking.

RFID Readers

Installed at fuel stations to scan tags and authorize fuel transactions.

Automated Fuel Dispensers

Control units integrated with fuel pumps ensure secure and monitored fuel dispensing.

Monitoring Software

Cloud-based software platforms display fuel reports, analytics, and operational insights.

Data Communication Network

Ensures secure and real-time transfer of fuel transaction data.

Benefits of Using an RFID Fuel Management System

Accurate Fuel Tracking

Automated data recording eliminates manual errors and ensures reliable fuel monitoring.

Reduced Fuel Theft

Only authorized vehicles and operators can access fuel, preventing misuse.

Operational Efficiency

Automation speeds up fueling operations and reduces administrative workload.

Cost Optimization

Detailed fuel reports help businesses identify inefficiencies and reduce fuel wastage.

Improved Accountability

Every fuel transaction is linked to a specific asset or operator.

Industries That Benefit from RFID Fuel Management Systems

Transportation and logistics companies

Marine and shipping industries

Construction and mining operations

Agriculture and farming businesses

Manufacturing and industrial facilities

Public transportation fleets

These industries depend heavily on fuel efficiency and accurate operational monitoring to remain profitable and competitive.

Challenges Solved by RFID Fuel Management Systems

Traditional fuel tracking methods can lead to several issues:

Unauthorized fuel usage

Manual reporting errors

Lack of real-time monitoring

Inefficient fuel allocation

High administrative workload

An RFID fuel management system addresses these challenges by automating the entire fuel monitoring process and providing real-time operational insights.

Integration with Digital Fleet Management

Modern RFID fuel management systems can be integrated with GPS tracking, telematics solutions, and fleet management software. This allows businesses to monitor not only fuel consumption but also vehicle routes, driving behavior, and operational performance.

By combining fuel data with telematics information, managers can make more informed decisions to optimize fuel usage and improve fleet efficiency.

Future Trends in RFID Fuel Management Systems

As technology continues to evolve, RFID fuel management systems are becoming more advanced and intelligent. Future trends may include:

AI-powered fuel consumption analysis

IoT sensor integration for advanced monitoring

Predictive maintenance alerts

Mobile app-based fuel monitoring dashboards

Automated fuel inventory management

These advancements will further enhance operational control and fuel efficiency for businesses worldwide.

Best Practices for Implementing an RFID Fuel Management System

Use high-quality RFID tags for durability and long-term performance

Train staff on automated fueling procedures

Monitor fuel analytics regularly to identify unusual consumption patterns

Integrate fuel systems with fleet management software

Establish clear fuel usage policies and operational guidelines

Proper implementation ensures long-term success and maximum return on investment.

Conclusion

An RFID fuel management system is a powerful solution for businesses seeking to improve fuel efficiency, reduce operational costs, and enhance fuel accountability. By automating fuel tracking and providing real-time insights, RFID technology enables organizations to maintain complete control over fuel operations.

As industries continue to adopt digital technologies, RFID fuel management systems will play a crucial role in modern fuel monitoring strategies. Companies that implement automated fuel control solutions today will benefit from increased transparency, improved operational efficiency, and long-term cost savings.