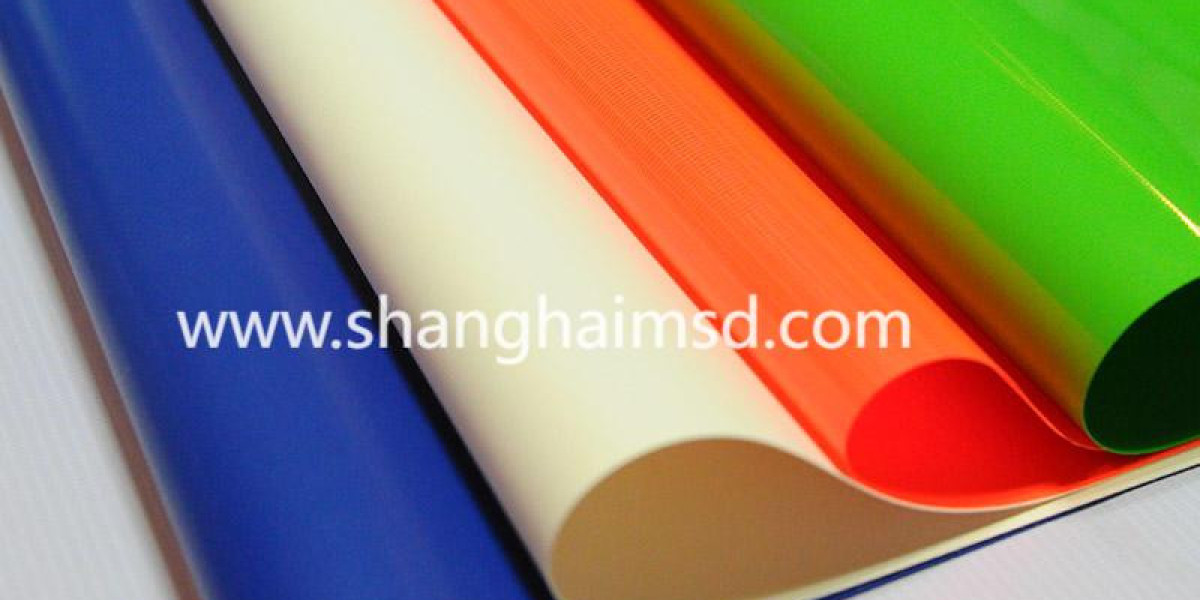

In the world of industrial materials and outdoor applications, PVC Tarpaulin Fabric has become a cornerstone for durability, versatility, and weather resistance. Unlike conventional textile materials, PVC tarpaulins are engineered through a meticulous manufacturing process that combines the strength of polyester with the flexibility of polyvinyl chloride (PVC) coating. This fusion results in a product that not only withstands harsh environmental conditions but also serves a wide range of uses—from truck covers and tents to construction membranes and advertising banners.

At the core of the process lies the creation of the polyester base cloth, typically a high-tenacity woven mesh. The polyester yarn is produced through an extrusion and spinning process that ensures uniform thickness and tensile strength. The weaving stage determines the mechanical properties of the final fabric, such as tear resistance and dimensional stability. The quality of this fabric directly influences how well it bonds with the PVC layer in subsequent stages, making it an essential foundation for reliable tarpaulin performance.

Once the base fabric is woven, the next stage involves coating or laminating it with liquid PVC resin. Two primary methods dominate the production process—knife coating and lamination. In knife coating, the molten PVC paste is evenly spread onto the fabric using precision machinery, forming a consistent, airtight layer. Lamination, on the other hand, involves bonding two PVC films with the polyester mesh sandwiched in between, using heat and pressure. Both methods ensure excellent adhesion and water resistance, but the knife-coating technique is often favored for heavy-duty outdoor applications where durability is critical.

Plasticizers, stabilizers, and pigments are added to the PVC compound to enhance flexibility, UV resistance, and color retention. This is one of the defining characteristics that distinguish PVC-coated fabrics from ordinary textile materials. The ability to incorporate additives allows manufacturers to fine-tune the properties of the fabric—making it flame retardant, mildew-resistant, or even recyclable. For instance, outdoor structures in humid environments benefit from anti-fungal coatings that prevent microbial degradation, extending the lifespan of the tarpaulin.

During the curing process, the coated fabric passes through a series of heated rollers to ensure uniform bonding and surface smoothness. The result is a material that is not only waterproof but also capable of withstanding temperature fluctuations, mechanical stress, and prolonged UV exposure. This combination of durability and adaptability explains why PVC tarpaulin fabric remains an indispensable choice for industries that demand long-term reliability.

An essential component of PVC tarpaulin’s success lies in its structural balance between flexibility and strength. The polyester core provides tensile stability, while the PVC layer contributes elasticity and resistance to external agents like moisture and chemicals. This synergy makes it suitable for both temporary and permanent installations, ranging from cargo containment to architectural canopies. Additionally, modern printing techniques allow for vibrant color application directly on the PVC surface, making it ideal for branding and signage purposes.

The environmental aspect of PVC tarpaulin manufacturing has also evolved significantly. Many producers are shifting toward eco-conscious formulations by reducing the use of harmful plasticizers and adopting recyclable PVC compounds. Energy-efficient coating systems further minimize emissions during production, aligning with global sustainability initiatives. This shift demonstrates that functional performance and environmental responsibility can coexist in industrial material innovation.

Shanghai MSD International Trading Co., Ltd. has been at the forefront of developing and distributing advanced PVC-coated fabrics that cater to both performance and sustainability requirements. With expertise in material engineering and process optimization, the company offers a diverse range of tarpaulin solutions suitable for global markets. To explore more about the production process and versatile applications of PVC-coated fabrics, visit https://www.shanghaimsd.com/news/what-is-pvc-tarpaulin-fabric.html .