Choosing the right home or light commercial charging setup takes more than a quick buy. You need a step-by-step plan, a code-aligned design, and a phased schedule that keeps life moving. We’ll walk through scope with a quality-first lens, so you power up without surprises. A little prep now prevents big headaches later. From panel capacity to cable routing, each decision shapes performance, safety, and future upgrades. If you’re coordinating with electrical services in havertown, ask about load calculations, breaker choices, and permits to make sure nothing stalls the project. Think of this as a playbook for reliable charging at home, the office, or a rental unit. You’ll see what to do, what to avoid, and how to keep budgets in check. Follow a proven sequence, and charging feels effortless and ready for tomorrow’s vehicles.

Map the project scope clearly for homes and light businesses

Start by defining where the charger lives, how cars approach, and what conduit runs make sense. You can review options electrical services in havertown before deciding on the final scope. Measure panel space, track daily mileage, and sketch cable routes that avoid tripping hazards. A townhome may require a wall-mount path along a shared drive. Documenting these details upfront saves returns and rework.

Separate essentials from extras to keep choices grounded. For a two-unit rental, you might call for two circuits, separate usage tracking, and lockable holsters. Homeowners often prefer shorter cords for tidier parking, and storefronts may add bollards to protect the equipment. Align features with real use. Clean scope makes permits faster, and reduces change orders later.

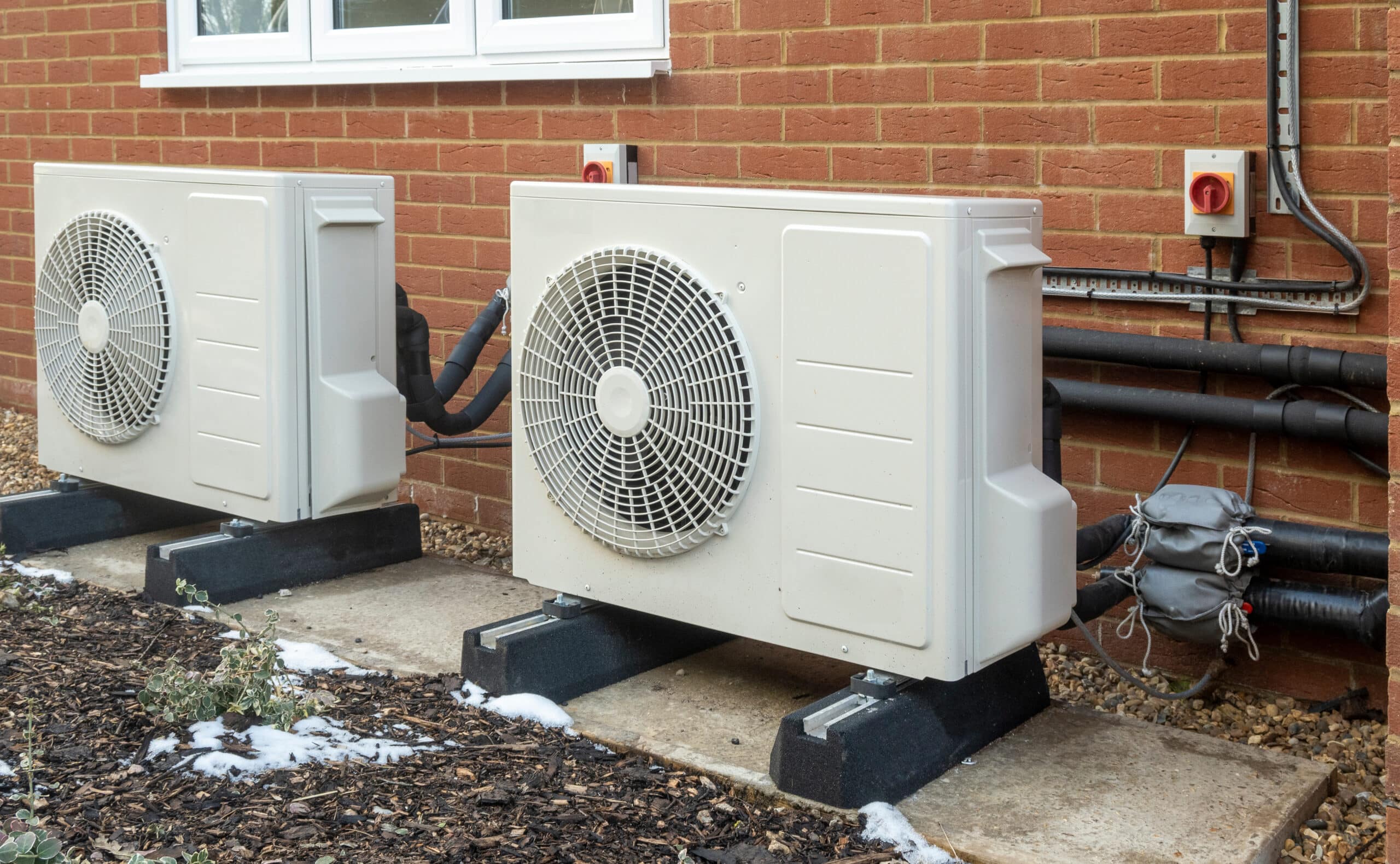

Choose components and site details that match climate and load

Focus on NEMA enclosure ratings, UV-stable cables, and fittings that suit local rain. Compare hardware lines electrical services in Havertown with different cord lengths, temperature ranges, and mounting kits. For a coastal shop, stainless hardware resists corrosion; for a snowy driveway, sloped pads manage meltwater. Thicker conductors deliver steady power over outdoor runs.

Pair breaker size to steady current, and plan for tomorrow’s higher amps. In a 1960s panel, aluminum feeders may need pigtails and joint compound. Indoor installs favor EMT to balance cost and ease of bends. Document part numbers in your bill of materials so installers deliver exactly what you planned. Future-ready parts keep expansion inexpensive.

Set a practical workflow and sequenced schedule for smooth delivery

Lock down permits, utility notifications, and HOA approvals before demolition starts. Coordinate milestone dates EV Charging Station so panel work, trenching, and inspections don’t collide. Mark conduit paths with paint, verify locates, and stage materials onsite by day. Test-mount hardware early to catch spacing issues.

Batch tasks that share tools to slash downtime. A small crew can pull conductors while the lead handles permit calls. Book asphalt cuts when weather is cooperative, and plate crossings for nightly safety. If supply delays pop up, swap tasks to keep progress moving. Clear daily checklists beat guesswork and limit idle hours.

Guard quality and manage risk with checks and verification

Use a pre-energization checklist that verifies torque, polarity, and GFCI function. Log results electrical services in Havertown alongside photos of terminations, conduit seals, and labeling. Do a megger on long runs catch nicks before they arc. Simulate load with a test rig to confirm temperatures stay within spec.

Inspect mounts and standoffs after the first week of use. Vibration from garage doors can loosen hardware without notice. IR scans reveal stressed connections under real charging cycles. A 15-minute audit prevents burns, and lets you fix tiny issues early. If anything’s fuzzy, tighten and clarify for the next user.

Balance costs and trade-offs across today and tomorrow

Start with a barebones path that’s safe, then stage add-ons over time. Compare phased plans EV charging station that lay conduit now and add extra circuits later. Running spare pipe beats new trenching if you expand parking. A modest cord reel now can become a stronger stand next year.

Cost alone misleads when reliability matters. A higher-cycle relay may outlast two cheaper units, lowering lifetime cost. Spend where failure is brutal, and trim cosmetic extras until usage proves you need them. Track utility rebates and credits to offset panel upgrades. Disciplined choices support easy expansion without overspending.

Conclusion: With scope mapped, parts matched to conditions, a tight schedule, and strong verification, you’re set up for dependable charging. The process above reduces risk while keeping budgets disciplined, so your system grows as needs shift. Revisit the plan each quarter to adjust for new vehicles, pricing, and routines. With careful upkeep and smart trade-offs, charging stays safe, efficient, and ready for what’s next.