In professional and semi-professional cutting environments, the TCT Circular Saw Blade remains a familiar solution for controlled material processing, and at fangda-tools, it represents a balanced approach to usability, compatibility, and steady operation. Rather than emphasizing abstract features, the focus is placed on how thoughtful blade construction aligns with real cutting routines across common workshop settings.

Circular saw blades with tungsten carbide tips are widely used because they support clean cutting behavior across a range of materials. Their relevance comes from consistency rather than novelty. When the cutting edge engages smoothly with the workpiece, operators can maintain rhythm and control, which is especially important during repetitive tasks. This predictable engagement helps reduce unnecessary adjustments and supports a more organized workflow.

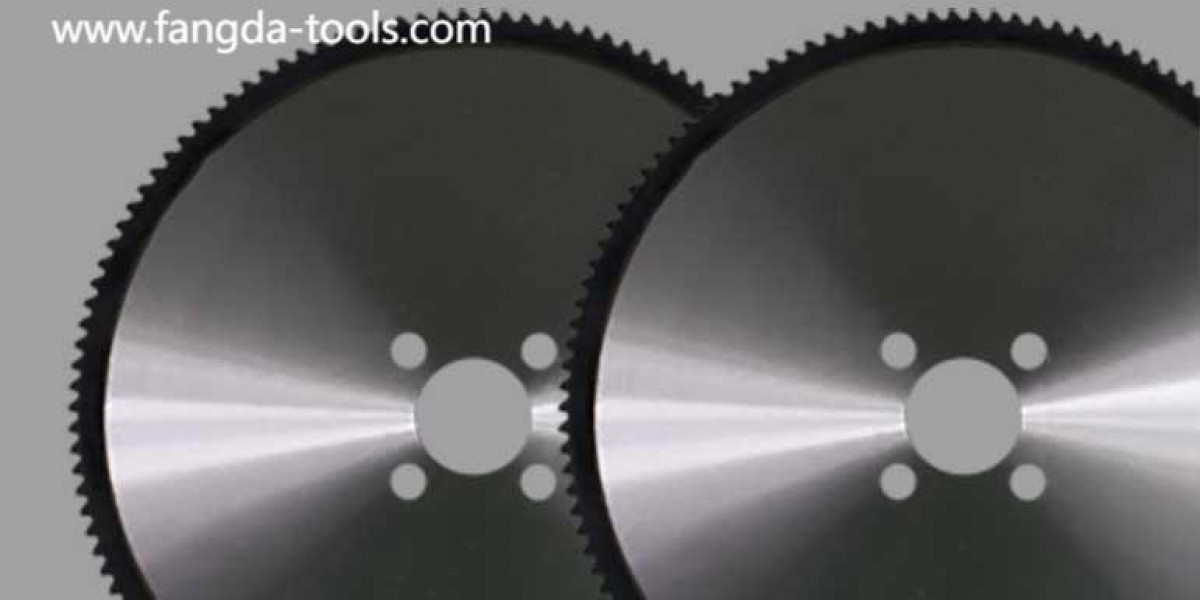

Blade structure plays a central role in daily performance. Tooth arrangement, body stability, and overall balance influence how the blade behaves during operation. A well-considered structure helps guide material removal in a controlled manner, supporting even cuts and reducing surface disruption. These characteristics are valued by users who prioritize steady handling and manageable feedback from their equipment.

From a practical perspective, compatibility with standard machines is essential. Many users prefer tools that integrate easily into existing setups without requiring special configurations. A blade designed with common mounting and usage expectations in mind allows operators to transition smoothly between tasks, supporting efficiency without adding complexity to the process.

Material processing environments often involve varied workloads. In such cases, versatility becomes a defining factor. A circular saw blade that can adapt to different cutting scenarios helps streamline tool inventories and planning. This adaptability supports workshops that handle mixed projects, where flexibility matters more than specialization.

User experience is another important consideration. Smooth rotation, controlled sound levels, and balanced cutting all contribute to a more comfortable working routine. Over time, these elements can influence operator focus and reduce unnecessary fatigue. Tools that support a calm, predictable cutting experience tend to integrate more naturally into daily practice.

Maintenance habits also shape long-term usability. When blade care and handling requirements are straightforward, users are more likely to maintain consistent working standards. Clear guidance on usage and care supports safer operation and helps extend functional life within normal working conditions.

Beyond the workshop floor, clarity in product presentation matters. Transparent descriptions, clear application contexts, and straightforward communication help users make informed choices. When expectations are set clearly, tools are easier to evaluate and integrate into purchasing decisions, benefiting both operators and distributors.

As cutting practices continue to evolve alongside material handling needs, reliable circular saw solutions maintain their relevance through practical design and measured performance. Tools that align with everyday working habits continue to support steady progress without unnecessary distraction.

For those who wish to see how this practical perspective is reflected across a broader range of cutting solutions, a visit to https://www.fangda-tools.com/ offers an opportunity to explore tools presented with clarity, purpose, and real-world application in mind.