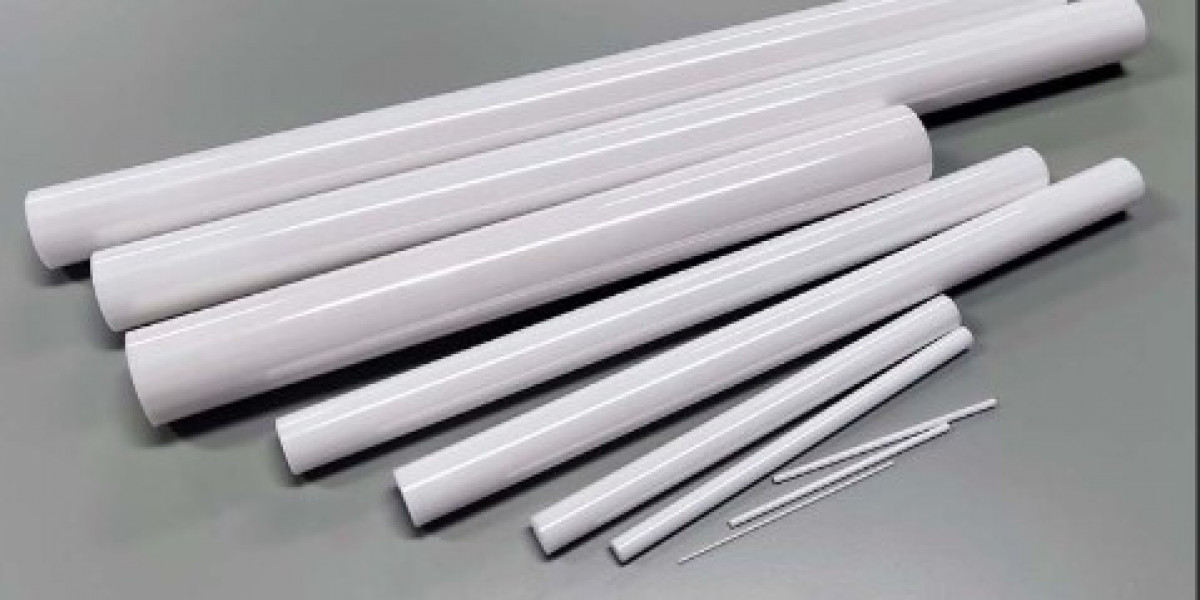

Zhufa Ceramic Rods stand out as versatile elements prized across numerous sectors for remarkable endurance against extreme conditions. These slender forms combine impressive hardness with thermal stability, making them indispensable where traditional materials falter. Professionals exploring reliable options often seek pieces capable of maintaining integrity amid intense heat, abrasion, or corrosive surroundings. Picture components performing consistently in furnace environments, precision instruments, or structural supports without degrading quickly. This steadfast quality stems from inherent properties that resist wear while offering electrical insulation and chemical inertness.

Delving deeper into what elevates these items reveals careful selection of base compositions like alumina or zirconia blends. Each variant brings distinct strengths, such as superior toughness or enhanced fracture resistance, allowing adaptation to specific challenges. Users appreciate how smoothly surfaces interact during motion, minimizing friction in moving assemblies. In high-temperature settings, stability prevents warping or cracking, ensuring longevity even through repeated cycles. Maintenance becomes straightforward since cleaning requires minimal effort and no special treatments.

Beyond core resilience, thoughtful finishing processes enhance overall usability. Polished exteriors reduce surface imperfections, promoting cleaner operation in sensitive applications. Compatibility with various attachments broadens possibilities, fitting seamlessly into measurement devices, guiding mechanisms, or protective sleeves. Industries involved in processing, electronics, or medical equipment frequently incorporate these elements to achieve greater precision and reliability. Adopting such materials often leads to quieter functioning and extended intervals between replacements.

Innovation continues shaping possibilities through refined production methods. Modern techniques focus on uniform density and controlled grain structure, resulting in consistent behavior across batches. This attention supports sustainability by decreasing waste and energy demands during creation. Customization avenues permit tailoring dimensions or profiles to match exact project needs, eliminating unnecessary modifications later.

Practitioners frequently share positive outcomes from integration. One engineer described improved accuracy in alignment tasks after switching, noting reduced vibration and steadier results. Another highlighted effortless handling during assembly, saving valuable time on complex setups. These experiences build conviction, encouraging others to consider similar upgrades. Dependable performance fosters ongoing collaboration with suppliers who prioritize quality throughout.

Global trends increasingly emphasize responsible sourcing and ethical practices. Producers committed to transparent operations gain preference from clients valuing integrity. Open communication about origins and processes reassures buyers, strengthening supply relationships. This alignment contributes to positive perceptions within professional communities focused on sustainable advancement.

As technologies evolve, demand grows for components engineered to handle escalating requirements. Forward-looking choices protect against future demands, maintaining efficiency in critical functions. Educational resources often introduce these fundamentals early, underscoring their importance in material science exploration.

Shifting toward collaborative perspectives, engaging knowledgeable providers yields valuable guidance. Discussions in specialized forums exchange practical tips, refining decisions effectively. Such interactions clarify nuances, benefiting newcomers and seasoned participants alike.

Curiously, the quiet strength embodied here sometimes parallels natural formations, where inherent toughness supports intricate designs without fanfare. This connection inspires appreciation for engineered solutions that operate discreetly yet powerfully.

Embracing superior material technology transforms routine applications into models of efficiency. Those ready to enhance their projects discover comprehensive selections at https://www.zfcera.com/product/ from Zhufa, prepared thoughtfully to fulfill diverse specifications.