Sintered filters are rigid, porous filtration components made by compacting and heat-fusing metal, polymer, or ceramic powders into a permeable structure that captures particulates while allowing controlled flow of liquids or gases. They are selected for stable pore geometry, mechanical strength, and resistance to heat, corrosion, and pressure cycling, with the added benefit of cleaning and reuse in many duty conditions. Sintered filters are widely used in chemical processing, oil and gas, water treatment, compressed air, and power systems where consistent filtration protects assets and supports product quality. Between 2025 and 2034, the market outlook remains constructive as industries raise purity standards, tighten emissions and discharge requirements, and adopt maintenance approaches that reduce downtime and consumable waste.

Market Overview and Industry Structure

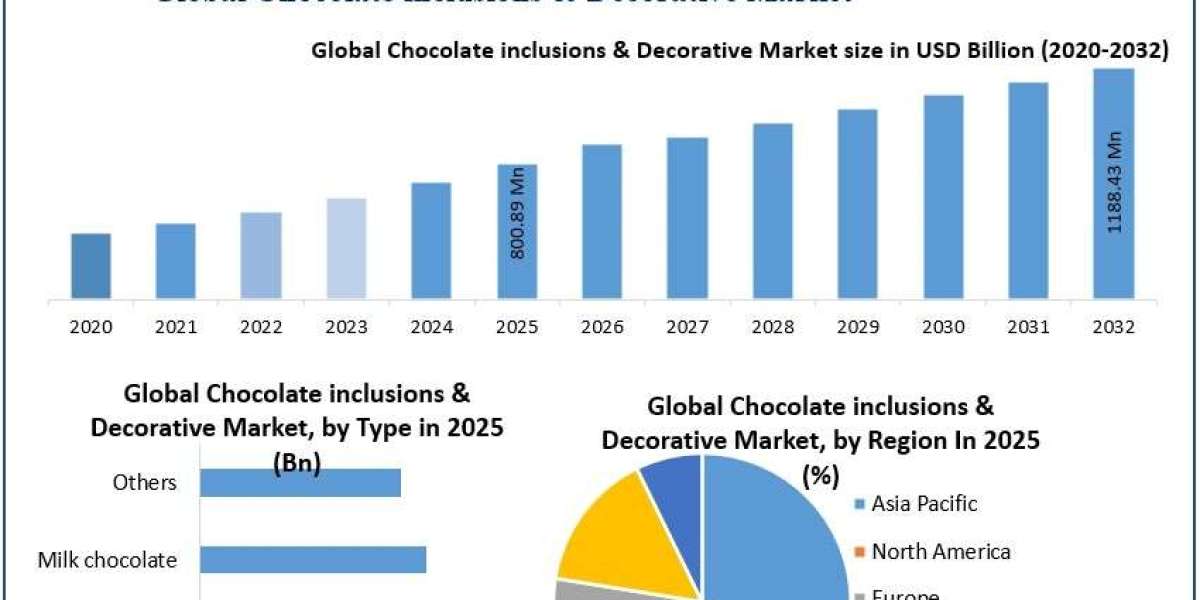

The Sintered Filter Market Size is valued at $1.27 Billion in 2025. Worldwide sales of Sintered Filter Market are expected to grow at a significant CAGR of 8.2%, reaching $2.2 Billion by the end of the forecast period in 2032.

The market spans porous metal elements (commonly stainless steel, nickel alloys, bronze, and titanium), sintered polymer elements for chemical compatibility and lighter weight, and ceramic variants for high-temperature or abrasive environments. Products are supplied as discs, tubes, cartridges, plates, and custom geometries integrated into housings and process skids. Industry participants include powder metallurgy specialists, filtration-focused manufacturers, OEM component suppliers, and distributors serving maintenance, repair, and operations.

Industry Size, Share, and Adoption Economics

Adoption economics are based on total filtration cost rather than unit price. In process plants, the cost of a filtration event includes production loss, labor, disposal, and equipment wear; reusable sintered elements can lower life-cycle cost through backflushing or regeneration and stable performance under harsh duty cycles. In regulated and high-purity environments, qualification testing, traceability, and validated cleaning protocols create moderate switching costs and support longer supplier relationships.

Latest Trends Shaping 2025–2034

Reusable filtration is gaining share as operators reduce landfill waste and extend maintenance intervals. Porosity engineering is advancing, with multilayer or gradient structures balancing lower pressure drop with higher capture efficiency and dirt-holding capacity. Another trend is integration with condition monitoring, especially differential pressure sensing, which supports condition-based maintenance and reduces premature changeouts.

Core Drivers of Demand

Stricter contamination control requirements are driving uptake in pharmaceuticals, food and beverage, specialty chemicals, and electronics-related manufacturing. Reliability-driven demand is strong in hydraulics, lubrication, compressors, and pneumatic systems where filtration protects valves, pumps, and actuators. Environmental compliance supports adoption in emission control and wastewater treatment where cleanable filters help manage particulate loads and reduce process variability.

Browse more information

https://www.oganalysis.com/industry-reports/sintered-filter-market

Challenges and Constraints

Sintered filters can be constrained by higher upfront cost and application fit. For ultra-fine or absolute filtration at very small particle sizes, membranes and depth media may be more appropriate. If pore structures are not optimized, pressure drop can increase energy use, especially in gas systems. Supply risks can emerge from powder availability, alloy price volatility, and energy-intensive sintering capacity. In regulated environments, extractables, cleaning chemistry compatibility, and documentation burdens can lengthen adoption cycles.

Market Segmentation Outlook

By material, the market includes stainless steel and nickel alloy, bronze-based, titanium, polymer, and ceramic sintered filters. By form factor, it includes cartridges, tubes, discs, plates, and custom integrated parts. By application, key segments include liquid process filtration, gas and compressed air filtration, hydraulic and lube filtration, catalyst and slurry filtration, and vent or exhaust filtration. By end user, major segments include chemical and petrochemical, oil and gas, water and wastewater, power, industrial machinery, food and beverage, life sciences, and electronics manufacturing. Channels split across OEM supply, project procurement, and aftermarket MRO distribution.

Key Market Players

- Parker Hannifin Corporation

- GKN Powder Metallurgy

- Porvair Filtration Group

- 3M Company

- Mott Corporation

- Filson Filters

- Hengko Technology Co., Ltd.

- Capstan Incorporated

- United Filters International

- Sintered Porous Metal Filters Co., Ltd.

- STI – Surface Technology International

- Baoji Fitow Metal Co., Ltd.

- MetPor

- Norman Filter Company

- Applied Porous Technologies, Inc.

Competitive Landscape and Strategy Themes

Competition centers on materials expertise, pore-size control, repeatable performance, and application engineering. Suppliers differentiate with corrosion-resistant alloys, high-temperature capability, low-dusting structures, and proven cleaning and refurbishment pathways. Strategy themes through 2034 include expanding high-purity portfolios, developing gradient-porosity products to cut energy use, and offering services such as refurbishment, performance testing, and standardized housings for faster maintenance. Regional stocking and faster customization are increasingly important as customers prioritize uptime.

Growth Opportunities by Region (2025–2034)

North America offers opportunities in chemicals, energy, and water infrastructure, especially for reusable elements and reliability upgrades. Europe favors cleanable filtration and circularity-linked procurement, supported by strict environmental standards. Asia-Pacific is expected to lead growth as industrial capacity and automation expand, increasing demand across gas and liquid filtration. Latin America presents selective opportunities tied to mining, energy, and water projects, with success depending on distribution reach. Middle East and Africa growth is supported by petrochemicals and desalination where corrosion resistance and long service life are valued.

Future Outlook & Forecast (2026–2034)

From 2026 to 2034, the market is expected to trend toward engineered filtration rather than purely volume growth. Sintered solutions should gain share where reusability, harsh duty cycles, and predictable performance reduce total cost of ownership. Innovation will focus on tighter micron control, lower-pressure-drop architectures, improved surface treatments for cleanability, and monitoring-enabled housings that support condition-based maintenance. Suppliers that pair technical credibility with resilient regional supply and refurbishment services will be best positioned.

Browse Related Reports

https://www.oganalysis.com/industry-reports/aromatic-secondary-amines-market

https://www.oganalysis.com/industry-reports/precast-concrete-release-agents-market

https://www.oganalysis.com/industry-reports/nano-silicon-powder-market

https://www.oganalysis.com/industry-reports/kaempferol-market

https://www.oganalysis.com/industry-reports/tall-oil-fatty-acid-market