The era in which the manufacturing industry finds itself is characterized by precision, flexibility, and innovation. Today, businesses do not require the production service alone but rather a partnership with a company that can ensure reliability, excellence, and value addition. This makes Leading Manufacturing Solutions the backbone for the sectors which function under tough and highly competitive conditions, including the energy sector, the construction sector, the automotive sector, and the heavy engineering sector among others.

Leading manufacturing solutions are based on the principles of advanced engineering and machinery and expertise in manufacturing and problem-solving. They involve more than production and focus on finding innovative solutions for challenging problems by means of intelligent design and execution. Companies that make use of such solutions have a strategic edge and are better positioned to respond to market requirements.

The Importance of Precision in Today’s Manufacturing Landscape

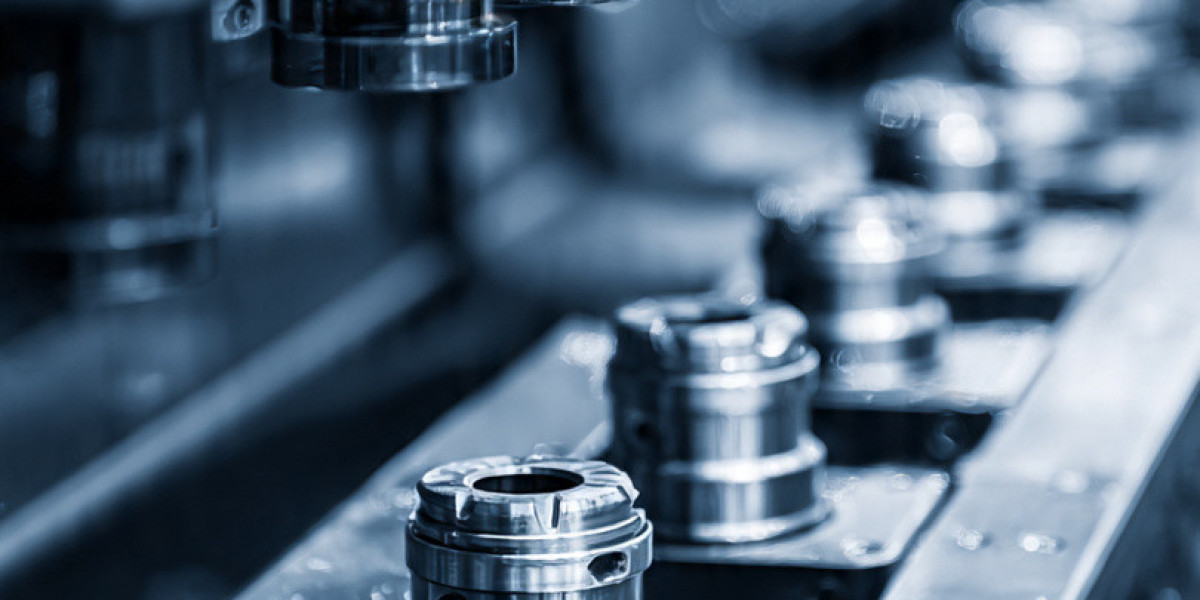

Precision has become the prime component of manufacturing performance. In fact, even slight departures from an as-designed condition may lead to inefficiency, added costs, or equipment failure. This is the point where Specialized Precision Manufacturing happens to play an important role in ensuring that every component fits into exact specifications and functions with belief in the real world. More than accuracy, precision manufacturing can accommodate repeatability, durability, and quality control at every stage of the production system.

As more and more industrial systems become complex, a manufacturer is supposed to make the components that can easily fit into other assemblies. To that effect, Specialized Precision Manufacturing allows such an accuracy with expert engineering using advanced CNC machining and rigorous inspection criteria and material knowledge. When precision is grouped together, then it will allow manufacturers to provide parts that enhance operational efficiency, extending equipment life.

How Leading Manufacturing Solutions Support Diverse Industries

Sectors like oil and gas, power, and industrial and infrastructure development require highly reliable and accurate components. The Best Manufacturing Solutions are developed with the aim of catering to such requirements, including the provision of flexibility in terms of production and the handling of both generic and highly customized requirements with ease. Such adaptability enables the catering to specific project requirements without affecting the timelines or the quality needed.

Precision Engineering Manufacturing makes this ability even more robust as manufacturers can design parts based on specific working conditions. Whether it is high pressure, temperature, or continuous working conditions, custom-precision parts are made to work efficiently. Manufacturing such parts would benefit industries as it would make them more stable, with less downtime.

Why Businesses Choose a Trusted Manufacturing Partner

The selection of a manufacturing partner has a crucial impact on the success of any project. Most companies find themselves attracted to manufacturers who present Leading Manufacturing Solutions because they possess both the expertise and the customer-centered orientation. An effective partner knows that each company faces its own set of problems.

Precision Engineering Manufacturing provides an additional value in the sense that it allows for customized production and not just standardized output. This means that businesses select the manufacturers based on their investment in technology, professionals, and quality management because such elements will promote reliability. Also, the elements of clarity and satisfaction of specifications are important factors.

Innovation and Technology as Key Differentiators

Innovation lies at the very core of Leading Manufacturing Solutions. This is due to the availability of advanced machinery and technology that enables increased accuracy and shortened lead times. It should be noted that such technology enables the manufacturing of complex parts with tighter tolerance and enhanced surface finishes. Consequently, the technology enables the production of quality products.

Precision Engineering Manufacturing receives significant benefits from innovations. Computer-controlled machining and analysis, real-time observation, and comprehensive quality analysis help make each part meet the exact specifications. As such, by adopting innovations, manufacturers can always remain ahead of the curve in terms of trends and make continuous improvements to produce better results.

Quality Assurance and Consistency in Manufacturing

Quality assurance is a major factor behind the success of a good manufacturing unit. Best Practices at the Leading Manufacturing Solutions follow a stringent quality control process to ensure that each product is of industry and client-approved standards. There are very few manufacturing solutions that overlook the significance of a quality output.

At Precision Engineering Manufacturing, quality assurance is an integrated process in production. Right from the selection of the material to final inspection, everything is monitored with the aim of ensuring accuracy and reliability. This approach assists in ensuring that the clients receive parts that function correctly, regardless of the conditions they are put in.

The Role of Expertise and Experience

Experience is an important aspect when it comes to the replication of accurate manufacturing results. The individuals offering the Best Manufacturing Solutions have experience accumulated over the years, which enables them to foresee problems before they arise, along with proposing effective solutions.

Precision Engineering Manufacturing is an area where a tremendous understanding concerning material science and manufacturing process expertise and project requirements is needed. Professional engineers and technicians with experience use their knowledge to make each part precision-manufactured. It is expertise in precision manufacturing that instills confidence within the clients to leave their projects in their skilled hands.

Conclusion

In the current cutthroat industrial scenario, it is imperative to make the right choice of the manufacturer to succeed. The Best Manufacturing Solutions offer companies the dependability, innovation, and precision required to outsmart the challenges of the market. As a combination of advanced technology, specialized expertise, and a focus on quality, manufacturers can produce outcomes that excel even the most demanding standards. Custom Precision Manufacturing Solutions further improve this aspect by catering to the exact requirements of every business operation.

FAQs

What makes Leading Manufacturing Solutions important for modern industries?

Leading Manufacturing Solutions are important because they focus on precision, reliability, and adaptability. They help industries meet complex requirements while maintaining quality and efficiency in production.

How does Custom Precision Manufacturing benefit industrial projects?

Custom Precision Manufacturing ensures that components are produced to exact specifications. This improves performance, reduces the risk of failure, and allows parts to integrate seamlessly into larger systems.

Why do companies prefer customized manufacturing over standard production?

Companies prefer customized manufacturing because it allows them to address specific operational challenges. Custom solutions offer better compatibility, improved durability, and optimized performance for unique applications.

How do manufacturers ensure consistent quality in precision manufacturing?

Consistency is achieved through advanced machinery, skilled professionals, and strict quality control processes. Continuous inspections and adherence to standards help maintain accuracy across all production stages.

Can precision manufacturing support multiple industries?

Yes, precision manufacturing supports a wide range of industries including oil and gas, construction, automotive, and heavy engineering by delivering reliable components designed for demanding conditions.