Indore Escorts & Call Girls Service With Free Hotel Facility Are you trying to find Escorts in Indore City? If so, you've come to the correct page. Indore Escorts is the top service agency for cash payments. We offer a vast array of exquisite Escorts that are ideal for anybody seeking a romantic and sensuous experience. Sujan Singh consistently extends discounts to both new and returning customers. When you book a Indore escort through her services, you may save up to 25%. Sujan Singh's charges begin at 4500, making it simple for everyone to fulfill their bodily needs. Indore Escorts Who Accept Cash Payment If you're seeking escorts in Indore City, you've come to the correct spot. The best Indore Escorts service provider accepting cash payments. We offer a vast array of exquisite Escorts that are ideal for anybody seeking a romantic and sensuous experience. We also consistently extends discounts to both new and returning customers. When you book a Indore escort through her services, you may save up to 25%. Sujan Singh's charges begin at 4500, making it simple for everyone to fulfill their bodily needs. In Indore, I offer escort services 24/7, with doorstep delivery to homes or hotel rooms in 20 to 30 minutes. Get Indore Escorts with a Room Reservation via WhatsApp number We place Indore Escorts flaming in the heat of passion in front of those who come to Indore for pleasure and to locate a nice lady; that girl is very modern to make you happy. He uses a number of instruments for this. She would stop at nothing to win your happiness. For those who are disappointed and have never experienced romance in their life, our escorts in Indore prove to be a godsend. Indore Escorts made their lives happier. Taxes restore those whose souls have completely perished because of love and passion. These women are acknowledged to receive great physical pleasure from our women. Our goal is to offer our clients novel and stimulating experiences. So, each month, we bring in new, attractive girls to our agency. She is an excellent worker as well. We provide Indore Escorts also Hire the most reliable call girls in Indore with our #1 Indore escorts agency. We provide top escorts service Indore and models to make the night sexy 24/7. ][Mumbai Escorts ][ ][Andheri Escorts ][ Bhubaneswar Escorts ][ Udaipur Escorts ][ Rajkot Escorts ][ Mira Road Escorts ][ Andheri Escorts ][ Ahmedabad Escorts ][ Nariman Point Escorts ][ Bandra Escorts ][ Airoli Escorts ][ Ambernath Escorts ][ Badlapur Escorts ][ Belapur Escorts ][ Bhandup Escorts ][ Bhayandar Escorts ][ Borivali Escorts ][ Chembur Escorts ][ Colaba Escorts ][ Cotton Green Escorts ][ Dadar Escorts ][ Dahisar Escorts ][ Diva Escorts ][ Dombivali Escorts ][ Ghansoli Escorts ][ Goddbonder Road Escorts ][ Goregaon Escorts ][ Govandi Escorts ][ Gtb Nagar Escorts ][ Indore Escorts ][ Juhu Escorts ][ Kalamboli Escorts ][ Kalwa Escorts ][ Kalyan Escorts ][ Kashimira Escorts ][ Kopar Khairane Escorts ][ Kurla Escorts ][ Lokhandwala Escorts ][ Malad Escorts ][ Mankhurd Escorts ][ Masjid Bunder Escorts ][ Mulund Escorts ][ Mumbra Escorts ][ Nahur Escorts ][ Navi Mumbai Escorts ][ Nerul Escorts ][ Panvel Escorts ][ Powai Escorts ][ Rabale Escorts ][ Sanpada Escorts ][ Santa Cruz Escorts ][ Seawood Escorts ][ Taloja Escorts ][ Thane Escorts ][ Tilak Nagar Escorts ][ Turbhe Escorts ][ Ulhasnagar Escorts ][ Vartak Nagar Escorts ][ Indore Escorts ][ Andheri Escorts ][ Chennai Escorts ][ Call Girls in Mumbai ][ Udaipur Escorts ][ Andheri Escorts ][ Pune Escorts ][ Hyderabad Escorts ][ Vashi Escorts ][ Vikhroli Escorts ][ Vile Parle Escorts ][ Wadala Road Escorts ][ Bangalore Escorts ][ Delhi Escorts ][ Gurgaon Escorts ][ Hyderabad Escorts ][ Jaipur Escorts ][ Kolkata Escorts ][ Lucknow Escorts ][ Noida Escorts ][ Patna Escorts ][ Pune Escorts ][ Ranchi Escorts ][ Surat Escorts ][ Bhopal Escorts ][ Ghaziabad Escorts ][ Allahabad Escorts ][ Jalandha Escorts ][ Jamshedpur Escorts ][ Varanasi Escorts ][ Rishikesh Escorts ][ Zirakpur Escorts ][ Vadodara Escorts ][ Mount Abu Escorts ][ Ajmer Escorts ][ Dehradun Escorts ][ Manali Escorts ][ Jammu Escorts ][ Haridwar Escorts ][ Kochi Escorts ][ Vijayawada Escorts ][ Visakhapatnam Escorts ][ Mathura Escorts ][ Raipur Escorts ][ Daman Escorts ][ Shimla Escorts ][ Agra Escorts ][ [https://www.mumbaaiescorts.in ][ Chennai Escorts ][ Indore Escorts ][ Ujjain Escorts ][ Badnawar Escorts ][ Badnagar Escorts ][ Shajapur Escorts ][ Ewas Escorts ][ Nagda Escorts ][ Ratlam Escorts ][ Sillod Escorts ][ Jalgaon Escorts ][ Bhusawal Escorts ][ Amalner Escorts ][ Ahmednagar Escorts ][ Dhule Escorts ][ Jalna Escorts ][ Udaipur Escorts ][ Kutch Escorts ][ Somnath Escorts ][ Porbandar Escorts ][ Aurangabad Escorts ][ Sabarmati Escorts ][ Cg Road Escorts ][ Vastrapur Escorts ][ Naroda Escorts ][ Narol Escorts ][ Sg Highway Escorts ][ Gota Escorts ][ Chandkheda Escorts ][ Ambawadi Escorts ][ Asarwa Escorts ][ Ashram Road Escorts ][ Satellite Escorts ][ Sarkhej Escorts ][ Paldi Escorts ][ Sola Escorts ][ Ranip Escorts ][ Shahpur Escorts ][ Thaltej Escorts ][ Vasna Escorts ][ Maninagar Escorts ][ Chopda Escorts ][ Chennai Escorts ][ Jalandhar Escorts ][ Jammu Escorts ][ Jhansi Escorts ][ Karnal Escorts ][ Kota Escorts ][ Kullu Escorts ][ Laddakh Escorts ][ Leh Escorts ][ Manipur Escorts ][ Meerut Escorts ][ Meghalaya Escorts ][ Mount Abu Escorts ][ Muzaffarnagar Escorts ][ Mysore Escorts ][ Nagpur Escorts ][ Nainital Escorts ][ Nashik Escorts ][ Navi Mumbai Escorts ][ Ooty Escorts ][ Pathankot Escorts ][ Pondicherry Escorts ][ Shimla Escorts ][ Sikkim Escorts ][ Siliguri Escorts ][ Champaner Escorts ][ Veraval Escorts ][ Surat Escorts ][ Vadodara Escorts ][ Ahmedabad Escorts ][ Agra Escorts ][ Dehradun Escorts ][ Gurgaon Escorts ][ Hyderabad Escorts ][ Jaipur Escorts ][ Jodhpur Escorts ][ Kanpur Escorts ][ Kolkata Escorts ][ Lucknow Escorts ][ Goa Escorts ][ Mumbai Escorts ][ Mussoorie Escorts ][ Raipur Escorts ][ Delhi Escorts ][ Ranchi Escorts ][ Rishikesh Escorts ][ Ajmer Escorts ][ Allahabad Escorts ][ Almora Escorts ][ Alwar Escorts ][ Ambala Escorts ][ Aravati Escorts ][ Bareilly Escorts ][ Bathinda Escorts ][ Bhilai Escorts ][ Bhopal Escorts ][ Bhubaneswar Escorts ][ Bikaner Escorts ][ Bilaspur Escorts ][ Coimbatore Escorts ][ Chandigarh Escorts ][ Daman Escorts ][ Darjeeling Escorts ][ Gangtok Escorts ][ Gorakhpur Escorts ][ Noida Escorts ][ Guwahati Escorts ][ Haldwani Escorts ][ Hapur Escorts ][ Imphal Escorts ][ Jabalpur Escorts ][ Jaisalmer Escorts ][ Anand Escorts ][ Gandhidham Escorts ][ Mehsana Escorts ][ Morbi Escorts ][ Palitana Escorts ][ Ambaji Escorts ][ Vapi Escorts ][ Ankleshwa Escorts ][ Adalaj Escorts ][ Dahod Escorts ][ Amreli Escorts ][ Dakor Escorts ][ Botad Escorts ][ Kandla Escorts ][ Diu Escorts ][ Mandvi Escorts ][ Anjar Escorts ][ Himmatnagar Escorts ][ Panchmahal Escorts ][ Sonipat Escorts ][ Srinagar Escorts ][ Tirupati Escorts ][ Tripura Escorts ][ Varanasi Escorts ][ Zirakpur Escorts ][ Kochi Escorts ][ Visakhapatnam Escorts ][ Airoli Escorts ][ Andheri Escorts ][ Bandra Escorts ][ Belapur Escorts ][ Borivali Escorts ][ Chembur Escorts ][ Colaba Escorts ][ Dadar Escorts ][ Dahisar Escorts ][ Dharavi Escorts ][ Ghatkopar Escorts ][ Goregaon Escorts ][ Grant road Escorts ][ Gonda Escorts ][ Navsari Escorts ][ Palanpur Escorts ][ Valsad Escorts ][ Nadiad Escorts ][ Godhra Escorts ][ Saputara Escorts ][ Juhu Escorts ][ Kandivali Escorts ][ Khar Escorts ][ Kharghar Escorts ][ Kurla Escorts ][ Lokhandwala Escorts ][ mahim Escorts ][ Malad Escorts ][ Marine Drive Escorts ][ Mira Road Escorts ][ Mulund Escorts ][ Nerulpanvel Escorts ][ Powai Escorts ][ Sakinaka Escorts ][ Santacruz Escorts ][ Seawood Escorts ][ Vasai Escorts ][ Vashi Escorts ][ Vileparle Escorts ][ Wadala Escorts ][ Worli Escorts ][ Rajkot Escorts ][ Junagadh Escorts ][ Jamnagar Escorts ][ Bhavnagar Escorts ][ Gandhinagar Escorts ][ Bhuj Escorts ][ Bharuch Escorts ][ Bangalore Escorts ][ Indore Escorts ][ Ahmedabad Escorts ][ Andheri Escorts ][ Bangalore Escorts ][ Bhopal Escorts ][ Bhubaneswar Escorts ][ Chennai Escorts ][ Daman Escorts ][ Delhi Escorts ][ Gurgaon Escorts ][ Hyderabad Escorts ][ Jaipur Escorts ][ Jamshedpur Escorts ][ Kochi Escorts ][ Kolkata Escorts ][ Mira Road Escorts ][ Mount Abu Escorts ][ Mumbai Escorts ][ Nagpur Escorts ][ Nashik Escorts ][ Navi Mumbai Escorts ][ Noida Escorts ][ Ooty Escorts ][ Pune Escorts ][ Rajkot Escorts ][ Ranchi Escorts ][ Surat Escorts ][ Tirupati Escorts ][ Udaipur Escorts ][ Vadodara Escorts ][ Vashi Escorts ][ Visakhapatnam Escorts ][ Call Girls in Aerocity || Call Girls in Agra || Call Girls in Ahmedabad || Call Girls in Ajmer || Call Girls in Akbarpur || Call Girls in Aligarh || Call Girls in Allahabad || Call Girls in Amritsar || Call Girls in Andheri || Call Girls in Aurangabad || Call Girls in Bandra || Call Girls in Bangalore || Call Girls in Bareilly || Call Girls in Bhopal || Call Girls in Bhubaneswar || Call Girls in Bilaspur || Call Girls in Chennai || Call Girls in Coimbatore || Call Girls in Cuttack || Call Girls in Darjeeling || Call Girls in Dehradun || Call Girls in Delhi || Call Girls in Dhanbad || Call Girls in Gangtok || Call Girls in Ghaziabad || Call Girls in Goa || Call Girls in Gurgaon || Call Girls in Guwahati || Call Girls in Gwalior || Call Girls in Haridwar || Call Girls in Hyderabad || Call Girls in Indore || Call Girls in Jaipur || Call Girls in Jalandhar || Call Girls in Jodhpur || Call Girls in Kanpur || Call Girls in Kochi || Call Girls in Kolkata || Call Girls in Lucknow || Call Girls in Ludhiana || Call Girls in Manali || Call Girls in Mira Road || Call Girls in Mount Abu || Call Girls in Mumbai || Call Girls in Nagpur || Call Girls in Nashik || Call Girls in Noida || Call Girls in Ooty || Call Girls in Pondicherry || Call Girls in Pune || Call Girls in Raipur || Call Girls in Rishikesh || Call Girls in Surat || Call Girls in Udaipur || Call Girls in Vadodara || Call Girls in Visakhapatnam || Call Girls in Zirakpur || Call Girls in Andheri || Call Girls in Mumbai || Udaipur Escorts || Indore Escorts || Mumbai Escorts Call Girls in Andheri || Aerocity Call Girls || Agra Call Girls || Ahmedabad Call Girls || Ajmer Call Girls || Akbarpur Call Girls || Aligarh Call Girls || Allahabad Call Girls || Amritsar Call Girls || Andheri Call Girls || Aurangabad Call Girls || Bandra Call Girls || Bangalore Call Girls || Bareilly Call Girls || Bhopal Call Girls || Bhubaneswar Call Girls || Bilaspur Call Girls || Chennai Call Girls || Coimbatore Call Girls || Cuttack Call Girls || Darjeeling Call Girls || Dehradun Call Girls || Delhi Call Girls || Dhanbad Call Girls || Gangtok Call Girls || Ghaziabad Call Girls || Goa Call Girls || Gurgaon Call Girls || Guwahati Call Girls || Gwalior Call Girls || Haridwar Call Girls || Hyderabad Call Girls || Indore Call Girls || Jaipur Call Girls || Jalandhar Call Girls || Jodhpur Call Girls || Kanpur Call Girls || Kochi Call Girls || Kolkata Call Girls || Lucknow Call Girls || Ludhiana Call Girls || Manali Call Girls || Mira Road Call Girls || Mount Abu Call Girls || Mumbai Call Girls || Nagpur Call Girls || Nashik Call Girls || Noida Call Girls || Ooty Call Girls || Pondicherry Call Girls || Pune Call Girls || Raipur Call Girls || Rishikesh Call Girls || Surat Call Girls || Udaipur Call Girls || Vadodara Call Girls || Visakhapatnam Call Girls || Zirakpur Call Girls || Andheri Call Girls || Indore Call Girls || Andheri Escorts || Call Girls in Ahmedabad Call Girls in Vadodara Call Girls in Andheri Call Girls in Bangalore Call Girls in Bhopal Call Girls in Bhubaneswar Call Girls in Chennai Call Girls in Daman Call Girls in Delhi Call Girls in Gurgaon Call Girls in Hyderabad Call Girls in Jaipur Call Girls in Jamshedpur Call Girls in Indore Call Girls in Kolkata Call Girls in Mira Road Call Girls in Mount Abu Call Girls in Mumbai Call Girls in Nagpur Call Girls in Ooty Call Girls in Noida Call Girls in Nashik Call Girls in Pune Call Girls in Ranchi Call Girls in Surat Call Girls in Tirupati Call Girls in Udaipur Call Girls in Kochi Ahmedabad Call Girls Vadodara Call Girls Andheri Call Girls Bangalore Call Girls Bhopal Call Girls Bhubaneswar Call Girls Chennai Call Girls Daman Call Girls Delhi Call Girls Gurgaon Call Girls Hyderabad Call Girls Jaipur Call Girls Jamshedpur Call Girls Indore Call Girls Kolkata Call Girls Mira Road Call Girls Mount Abu Call Girls Mumbai Call Girls Nagpur Call Girls Ooty Call Girls Noida Call Girls Nashik Call Girls Pune Call Girls Ranchi Call Girls Surat Call Girls Tirupati Call Girls Udaipur Call Girls Call Girls in Aerocity || Call Girls in Agra || Call Girls in Ahmedabad || Call Girls in Ajmer || Call Girls in Akbarpur || Call Girls in Aligarh || Call Girls in Allahabad || Call Girls in Amritsar || Call Girls in Andheri || Call Girls in Aurangabad || Call Girls in Bandra || Call Girls in Bangalore || Call Girls in Bareilly || Call Girls in Bhopal || Call Girls in Bhubaneswar || Call Girls in Bilaspur || Call Girls in Chennai || Call Girls in Coimbatore || Call Girls in Cuttack || Call Girls in Darjeeling || Call Girls in Dehradun || Call Girls in Delhi || Call Girls in Dhanbad || Call Girls in Gangtok || Call Girls in Ghaziabad || Call Girls in Goa || Call Girls in Gurgaon || Call Girls in Guwahati || Call Girls in Gwalior || Call Girls in Haridwar || Call Girls in Hyderabad || Call Girls in Indore || Call Girls in Jaipur || Call Girls in Jalandhar || Call Girls in Jodhpur || Call Girls in Kanpur || Call Girls in Kochi || Call Girls in Kolkata || Call Girls in Lucknow || Call Girls in Ludhiana || Call Girls in Manali || Call Girls in Mira Road || Call Girls in Mount Abu || Call Girls in Mumbai || Call Girls in Nagpur || Call Girls in Nashik || Call Girls in Noida || Call Girls in Ooty || Call Girls in Pondicherry || Call Girls in Pune || Call Girls in Raipur || Call Girls in Rishikesh || Call Girls in Surat || Call Girls in Udaipur || Call Girls in Vadodara || Call Girls in Visakhapatnam || Call Girls in Zirakpur || Call Girls in Andheri || Call Girls in Mumbai || Udaipur Escorts || Indore Escorts || Call Girls in Andheri || http://d.escorts.org.in/ http://c.escorts.org.in/ http://bng.escorts.org.in/ http://bho.escorts.org.in/ http://aurangabad.escorts.org.in/ http://ag.escorts.org.in/ http://and.escorts.org.in/ https://i.escorts.org.in https://mi.escorts.org.in http://manali.escorts.org.in/ http://bbsr.escorts.org.in/ http://mussoorie.escorts.org.in/ http://mroad.escorts.org.in/ http://mabu.escorts.org.in/ http://a.escorts.org.in/ http://ahm.escorts.org.in/ http://nagpur.escorts.org.in/ http://nainital.escorts.org.in/ http://nashik.escorts.org.in/ http://ooty.escorts.org.in/ http://p.escorts.org.in http://rajkot.escorts.org.in/ http://raipur.escorts.org.in/ http://ranchi.escorts.org.in/ http://rishikesh.escorts.org.in/ http://roorkee.escorts.org.in/ http://sur.escorts.org.in/ http://v.escorts.org.in http://vis.escorts.org.in http://upr.escorts.org.in/ http://h.escorts.org.in/

Recherche

Messages populaires

-

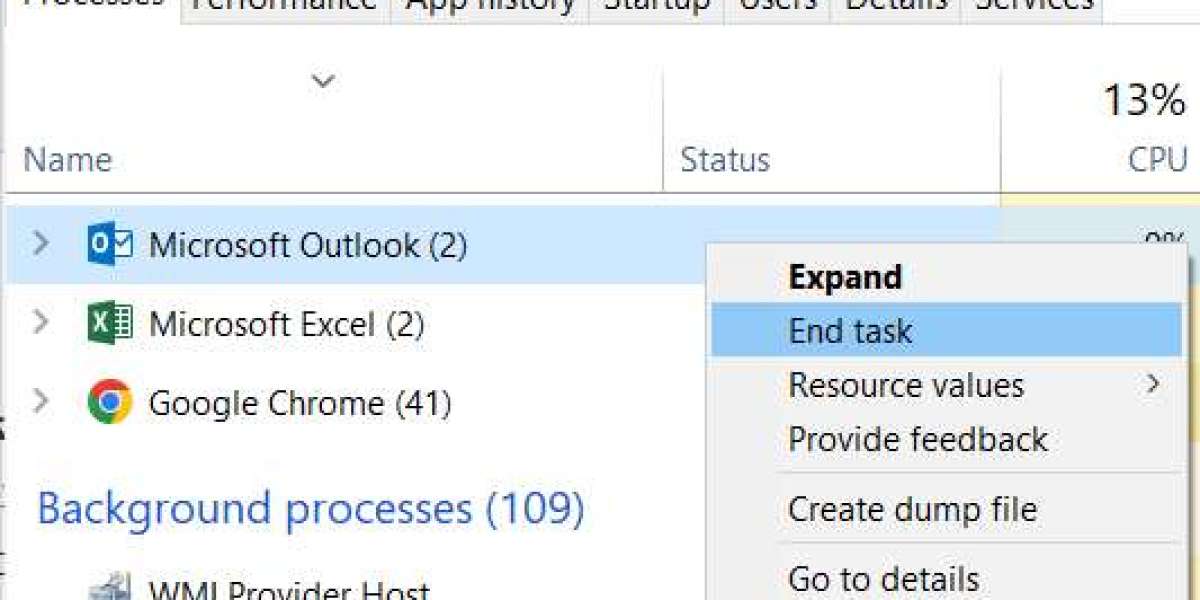

Repair an Office application

Par ashlykime82679

Repair an Office application

Par ashlykime82679 -

Poker Room Online Non AAMS: Analisi delle Dinamiche Competitive e Implicazioni per il Giocatore Italiano

Par devidweb

Poker Room Online Non AAMS: Analisi delle Dinamiche Competitive e Implicazioni per il Giocatore Italiano

Par devidweb -

Outlook 2013 2016 stuck on "loading profile" for about 30 seconds Software & Applications

Par harrisleong515

Outlook 2013 2016 stuck on "loading profile" for about 30 seconds Software & Applications

Par harrisleong515 -

Global Power Steering Fluids Market Industry Insights, Trends, Outlook, Opportunity Analysis Forecast To 2025-2034

Par kertina2

Global Power Steering Fluids Market Industry Insights, Trends, Outlook, Opportunity Analysis Forecast To 2025-2034

Par kertina2 -

Tree Service Springfield Tips for Safer Trees

Par latoshaoliver1