Delays and excess storage slowly eat into profit. A clear view of Home Goods Distribution shows where money leaks out. Once leaders see the gaps, they can act fast. Direct action leads to quick savings.

Cost control begins with clean and accurate data. Companies should track shipping time, handling effort, and storage fees. When numbers are clear, weak areas stand out. Teams can remove duplicate tasks and shorten movement paths. Even small layout changes can reduce labor hours. Strong reporting supports smart decisions. This discipline cuts guesswork and repeated errors.

Smarter Inventory Planning

Inventory is cash sitting on shelves. Too much stock, including overstock housewares, locks up money and space. Too little stock causes rush shipping and lost sales. Balanced planning keeps operations steady. Forecast tools help teams predict buying trends. That insight improves Home Goods Distribution by matching stock to demand. Fewer surprises lower emergency spending.

Clear reorder rules protect margins. Automated alerts stop overbuying and stockouts. Warehouse teams feel more confident when stock stays stable. Accurate counts reduce lost or misplaced goods. Better planning lowers carrying costs over time. Products move in a smooth and steady flow. Managers can then focus on growth instead of fixing problems.

Warehouse Layout and Process Efficiency

A smart warehouse layout saves time on every order. Workers should walk the shortest path possible. Fast moving goods belong near packing areas. Logical placement reduces confusion and search time. Efficient layouts support Home Goods Distribution by speeding up picking and packing. Faster work lowers labor costs without hurting accuracy.

Standard procedures create consistent results. Clear labels prevent sorting mistakes. Simple workflows help new staff learn faster. Teams waste less time fixing errors. Organized paths also improve safety. Clean spaces support steady output. Minutes saved each day build into major savings.

Transportation Optimization

Shipping is often the biggest expense in distribution. Poor routing wastes fuel and driver hours. Smart route planning cuts extra miles. Load consolidation reduces the number of trips. These steps improve Home Goods Distribution by lowering freight costs. Better planning also strengthens delivery reliability.

Carrier choice matters just as much. Businesses should review rates and service often. Long partnerships can unlock better pricing. Real time tracking keeps customers informed. Visibility prevents disputes and delays. Predictable transit builds customer trust. Reliable shipping protects both cost control and brand image.

Technology and Automation That Pay Off

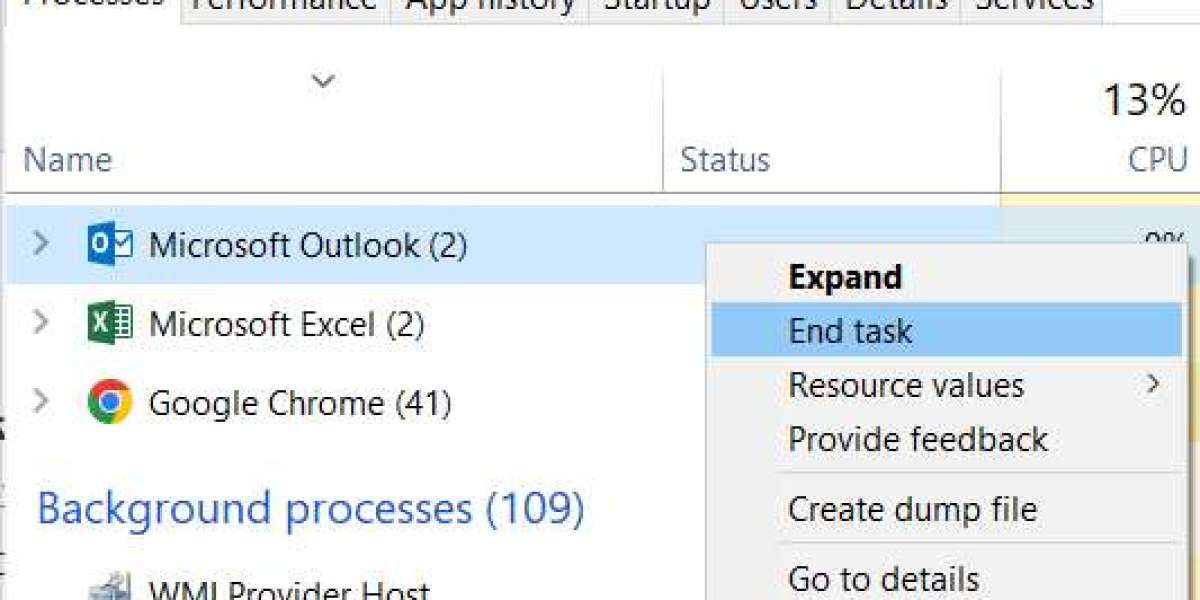

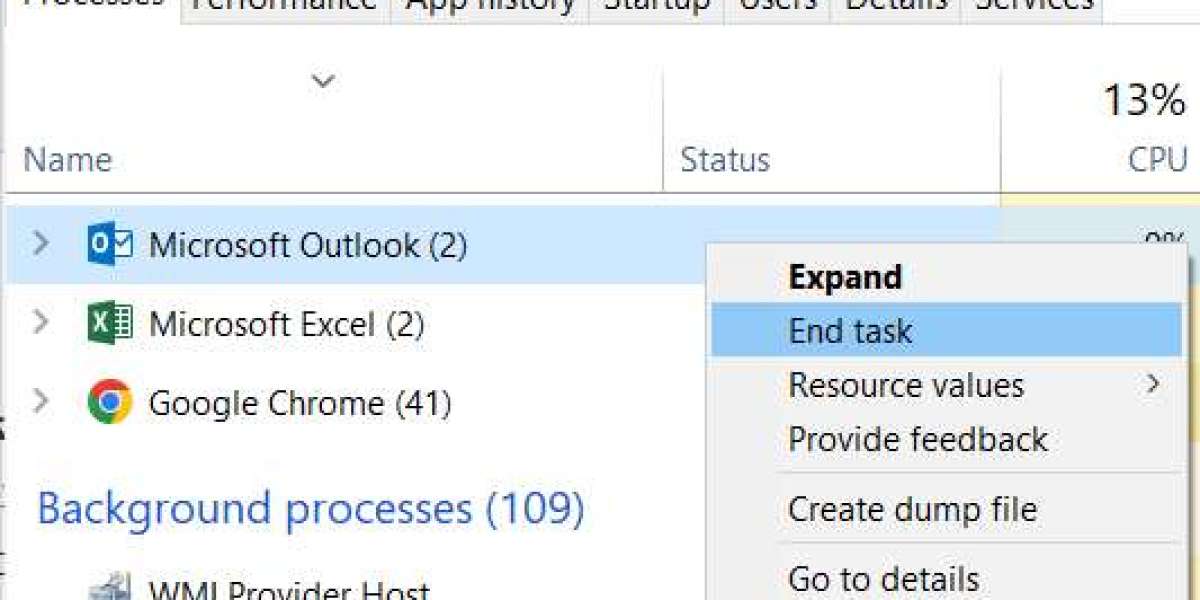

Automation removes slow manual work. Barcode scanning speeds up receiving and picking. Warehouse software reduces paperwork and human mistakes. These tools improve Home Goods Distribution by boosting speed and accuracy. Workers can focus on higher value tasks. Output rises without adding more labor.

Digital systems improve communication across teams. Inventory updates appear instantly. Managers see live performance data. Quick insights allow fast corrections. Automation prevents costly surprises. Smart technology investments pay back through efficiency. Over time, these tools become a strong advantage.

Supplier and Vendor Coordination

Strong supplier ties stabilize operations. Clear agreements avoid confusion about delivery timing. Vendors who understand expectations ship more reliably. Tight coordination improves Home Goods Distribution by cutting delays at the source. Early communication prevents last minute stress.

Shared forecasts help both sides plan better. Suppliers manage production with more accuracy. Businesses receive goods at the right time. Mutual trust supports quick problem solving. Issues get resolved faster when partners cooperate. Smooth relationships reduce friction in the chain. Goods continue to flow without disruption.

Packaging and Handling Improvements

Packaging affects both safety and cost. Oversized boxes waste shipping space and money. Smart sizing reduces dimensional weight fees. Protective materials prevent damage and returns. These changes strengthen Home Goods Distribution by lowering loss and transport expenses. Better packaging also speeds handling.

Standard packing rules simplify training. Workers pack goods safely and consistently. Damage claims drop when products travel securely. Fewer returns protect profit margins. Customers receive items in good shape. Positive delivery experiences drive repeat business. Efficient packaging supports savings and satisfaction.

Data Driven Performance Management

Regular measurement leads to smarter decisions. Key metrics show how operations truly perform. Managers should track speed, accuracy, and shipping cost. Frequent reviews catch trends before they grow expensive. Data focused oversight keeps Home Goods Distribution aligned with goals. Clear targets guide improvement.

Teams perform better when goals are visible. Dashboards build accountability. Small improvements add up over time. Leaders can reward efficiency and correct weak areas. Transparent reporting builds trust across departments. Consistent tracking sustains progress. Improvement becomes part of daily work.

Workforce Training and Accountability

Well trained staff reduce mistakes and delays. Clear instruction builds confidence and speed. Employees who understand the process work more efficiently. Strong onboarding supports steady Home Goods Distribution by lowering costly errors. Skilled workers solve issues quickly.

Ongoing training keeps abilities sharp. Refresher sessions reinforce best practices. Cross training adds flexibility during peak demand. Teams adjust smoothly when workloads change. Accountability systems promote ownership of results. Workers take pride in strong performance. Skilled teams protect service quality and profit.

Conclusion: Building a Lean and Reliable Operation

Streamlining distribution requires focus and discipline. Every improvement should support cost control and service quality. Businesses that study workflows uncover real savings. Smart planning, strong technology, and trained teams create a solid base. Effective Home Goods Distribution relies on steady execution, not guesswork. Commitment to improvement drives lasting efficiency.

Cutting costs does not mean lowering standards. It means removing waste and strengthening systems. Smooth operations deliver better customer service. Profit improves without sacrificing reliability. Clear goals guide each decision. Sustainable processes support long term growth. A lean distribution model sets any home goods business up for success.