The Global Food Robotics Market has emerged as a transformative force in the food processing and packaging industry, redefining efficiency, precision, and safety standards. Food robotics refers to the use of robotic systems and automation technologies in tasks such as sorting, packaging, cooking, processing, and handling food products. The adoption of these solutions is driven by the need to enhance operational efficiency, reduce labor costs, ensure consistent quality, and maintain stringent hygiene standards. The integration of robotics in the food sector is also responding to growing consumer demand for safe, high-quality, and traceable food products.

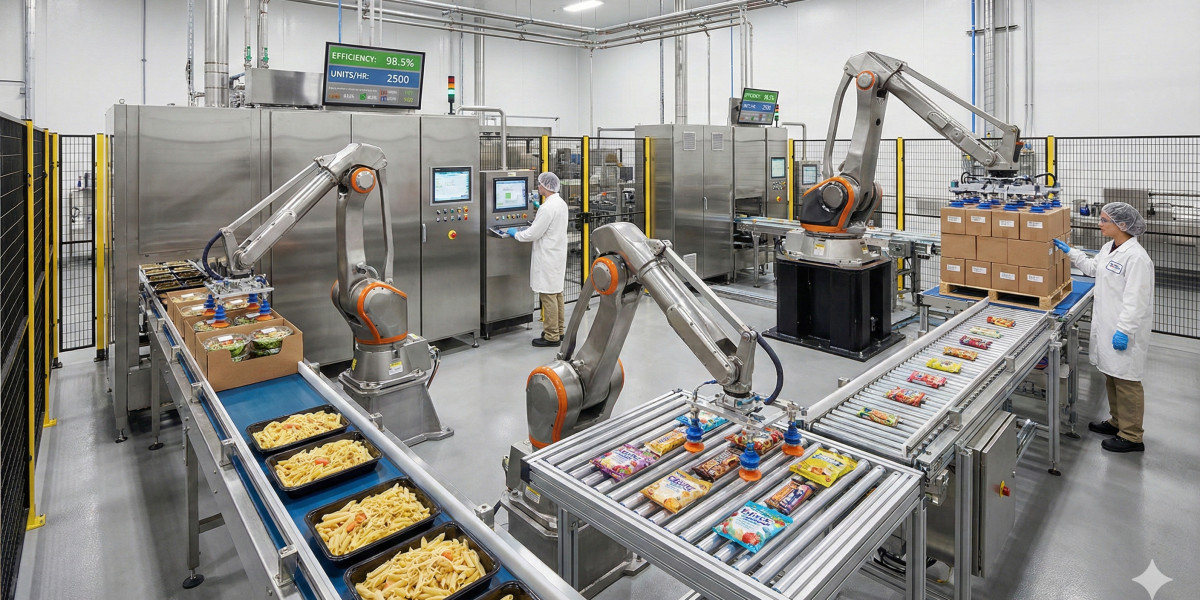

As the global food industry grapples with rising labor costs, workforce shortages, and increasing production demands, food robotics is positioned to offer scalable solutions. From automated sorting systems in fresh produce processing to robotic arms for packaging and palletizing, these technologies are reshaping production lines and supply chains. The market is witnessing rapid technological advancements, including AI-driven robots, collaborative robots (cobots), and autonomous mobile robots, enabling flexible and adaptive operations.

Market Overview

The Global Food Robotics Market was valued at USD 3.0 billion in 2024 and is projected to reach USD 6.9 billion by 2033, growing at a CAGR of 9.9% over the forecast period. This growth reflects the increasing need for automation across various food industry segments, driven by efficiency improvements, labor optimization, and compliance with stringent food safety regulations. Food robotics solutions are particularly critical in high-volume production environments, where precision and speed directly impact profitability and operational effectiveness.

The market growth is further propelled by innovations in robotics technology, such as machine learning-enabled automation, computer vision systems for quality inspection, and flexible robotic arms capable of performing complex tasks. These innovations not only increase throughput but also reduce human exposure to hazardous or repetitive tasks, improving workplace safety and reducing the risk of contamination in food processing environments.

Market Dynamics

The growth of the Food Robotics Market is influenced by a combination of technological, economic, and regulatory factors. One of the primary drivers is the rising labor cost and scarcity of skilled personnel in the food processing sector. Robotics offers a solution to automate repetitive, labor-intensive tasks, enabling manufacturers to maintain consistent production levels without relying heavily on manual labor.

The increasing focus on food safety and hygiene is another key factor supporting market expansion. Automation minimizes direct human contact with food products, thereby reducing the risk of contamination and improving compliance with regulatory standards. Governments and industry bodies in various regions are also implementing stricter guidelines for food safety, which is further encouraging the adoption of robotics solutions.

Moreover, the demand for high-quality and visually appealing packaged foods is driving the need for precision in processing and packaging. Robotics provides consistent and accurate handling, ensuring product uniformity and reducing wastage. Additionally, the growing trend of ready-to-eat and processed foods is fueling demand for automated solutions capable of handling large volumes efficiently.

Product Type Analysis

The Food Robotics Market can be segmented based on product types, including robotic arms, automated guided vehicles (AGVs), automated picking and sorting systems, collaborative robots, and specialized end-effectors for food handling. Robotic arms are widely used for tasks such as packaging, palletizing, and processing due to their versatility and precision. Collaborative robots, designed to work alongside human operators, are gaining popularity for smaller-scale operations and tasks requiring flexible handling.

Automated picking and sorting systems are essential in processing fruits, vegetables, and baked goods, where speed and accuracy are critical. AGVs and autonomous mobile robots facilitate the efficient transportation of raw materials and finished products within production facilities, improving overall workflow efficiency. The integration of AI and machine learning in these systems allows for real-time adjustments, predictive maintenance, and adaptive operations.

Application Analysis

Food robotics finds applications across various sectors within the food industry. In food processing, robots are employed for cutting, slicing, dicing, and portioning, ensuring uniformity and reducing manual labor. In packaging, robotics automates the tasks of filling, sealing, labeling, and palletizing, enhancing speed and accuracy while minimizing product damage. In the bakery and confectionery sector, robots assist with decorating, handling delicate products, and packaging complex items.

The catering and hospitality sectors are also increasingly adopting robotics for cooking, assembling meals, and serving customers. These applications help reduce labor dependency and improve operational efficiency, particularly in high-volume food service environments. Additionally, robotics is increasingly used for quality inspection, employing computer vision and AI to detect defects, ensure compliance with standards, and reduce wastage.

End User Analysis

The primary end users of food robotics include food and beverage manufacturers, restaurants and catering services, bakery and confectionery units, and logistics and packaging companies. Large-scale food manufacturers benefit from robotics by achieving higher production throughput, consistent product quality, and compliance with hygiene regulations. Restaurants and catering services leverage collaborative robots to streamline kitchen operations, reduce waiting times, and maintain consistent food quality.

Bakery and confectionery units employ specialized robots for decorating and packaging, where precision and aesthetic quality are critical. Logistics and packaging companies utilize automated solutions for handling, sorting, and palletizing, reducing manual handling errors and increasing operational efficiency. Overall, the diverse range of end users highlights the broad applicability and importance of robotics across the food industry value chain.

Technological Trends

The Food Robotics Market is characterized by rapid technological advancements. AI-powered robotics are enhancing adaptability and decision-making capabilities, allowing robots to recognize objects, detect defects, and adjust operations in real time. Computer vision systems integrated with robotics facilitate automated quality inspection, ensuring only high-quality products reach consumers.

Collaborative robots (cobots) are gaining traction for tasks that require human-robot interaction, combining precision and flexibility with safety features. Autonomous mobile robots (AMRs) are increasingly deployed in warehouses and production floors for efficient material handling, reducing bottlenecks and operational downtime. Furthermore, the integration of IoT and cloud computing enables real-time monitoring, predictive maintenance, and data-driven decision-making, optimizing the performance of robotic systems.

Regional Analysis

The Food Robotics Market in 2023 revealed varied regional dynamics, with Asia-Pacific accounting for an approximate 45% market share. This dominance is attributed to rapid industrialization, substantial investments in automation systems, and growing demand for efficient food processing and packaging solutions in countries like China, Japan, and India. The region boasts a strong manufacturing base and a rising focus on food safety, quality assurance, and production efficiency, reinforcing its position at the forefront of the global market.

North America and Europe represent mature markets, driven by technological adoption, high labor costs, and stringent food safety regulations. The presence of established food processing companies and ongoing investments in advanced robotics solutions contribute to market growth. The Middle East & Africa and Latin America are emerging markets, witnessing increasing adoption of food robotics due to expanding food processing facilities, growing urbanization, and rising disposable incomes.

Download a Complimentary PDF Sample Report : https://dimensionmarketresearch.com/report/food-robotics-market/request-sample/

Competitive Landscape

The Food Robotics Market is highly competitive, with players focusing on technological innovation, strategic collaborations, and customized solutions for diverse applications. Companies are investing in research and development to enhance robot performance, precision, and reliability while ensuring cost-effectiveness. Strategic partnerships with food manufacturers, packaging companies, and technology providers facilitate the integration of robotics into existing production lines, enabling faster adoption and scalability.

Innovation in end-effectors, AI-based vision systems, and cobot designs are key areas of focus. Market participants are also exploring robotics-as-a-service models, providing flexible deployment options and reducing upfront investment costs for end users.

Future Outlook and Opportunities

The future of the Food Robotics Market is highly promising, driven by increasing automation adoption, technological advancements, and growing demand for safe and efficient food production. Emerging economies in Asia-Pacific, Latin America, and the Middle East are expected to witness substantial growth due to rising industrialization, urbanization, and investment in food infrastructure.

The adoption of sustainable and energy-efficient robotics solutions is expected to rise, as environmental considerations become integral to food processing operations. Moreover, the integration of AI, machine learning, and IoT in robotics systems will enhance operational efficiency, predictive maintenance, and real-time monitoring, creating new growth avenues. The continued emphasis on reducing labor dependency and improving productivity is anticipated to further accelerate market expansion.

FAQs

What is food robotics used for?

Food robotics is used to automate tasks in food processing, packaging, handling, and quality inspection, improving efficiency, consistency, and safety.

What factors are driving the growth of the Food Robotics Market?

Rising labor costs, demand for operational efficiency, stringent food safety regulations, and technological advancements are the primary growth drivers.

Which region leads the Food Robotics Market?

Asia-Pacific leads the market with a 45% share, driven by industrialization, investment in automation, and demand for efficient food processing solutions.

What types of robots are used in food processing?

Robotic arms, collaborative robots, automated guided vehicles, picking and sorting systems, and specialized end-effectors are commonly used in food processing.

How does automation improve food safety?

Automation reduces direct human contact with food products, minimizes contamination risk, and ensures consistent hygiene and quality standards.

Summary of Key Insights

The Food Robotics Market is poised for strong growth, projected to reach USD 6.9 billion by 2033 at a CAGR of 9.9%. Market expansion is driven by rising labor costs, increasing automation adoption, and the need for efficient and hygienic food processing solutions. Asia-Pacific leads the market, supported by industrialization, investment in automation systems, and strong food manufacturing capabilities. Technological advancements, including AI, IoT, and collaborative robots, are redefining operations across the food industry. Sustainability, operational efficiency, and food safety remain key focus areas, shaping the future of the market.

Purchase the report for comprehensive details : https://dimensionmarketresearch.com/checkout/food-robotics-market/