Early decisions about enclosure selection shape long-term reliability, so specifying a Electrical Socket Box in the middle of project planning ensures correct ingress protection and convenient cable routing, and choosing the right Electrical Socket Box up front avoids costly retrofits while standardizing spare parts and maintenance procedures. Outdoor and industrial installations place special demands on outlet housings: they must protect live parts from moisture and dust, provide safe access for technicians, and allow tidy cable management without compromising sealing or mechanical strength.

What an outlet enclosure must protect against

An outlet enclosure faces more than rain. Dust, salt spray, UV exposure, temperature swings, and accidental mechanical impact all threaten internal components. The enclosure must therefore combine a robust shell with reliable sealing details — continuous gaskets, captive clamps, and reinforced lid flanges. Consideration for pressure-equalizing vents prevents internal condensation without inviting water ingress, and specifying the correct ingress protection (IP) rating for the environment reduces the chance of premature failures.

Materials, finishes, and corrosion resistance

Material selection is critical to longevity. Stainless steel and powder-coated aluminium resist corrosion in coastal and industrial areas, while reinforced thermoplastics provide impact resistance and electrical insulation in lighter-duty applications. Fasteners, hinges, and hardware should match the corrosion resistance of the enclosure body to prevent galvanic issues and seizure. UV-stable coatings and color-fast finishes reduce aesthetic degradation and preserve protective coatings over years of direct sun exposure.

Installing to preserve protection and serviceability

Even the best-designed enclosure will fail if installed incorrectly. Use reinforced backing where panels are mounted to prevent deformation from repeated access or impact. Orient cable entries to avoid direct water pathways and use correctly sized cable glands with integrated strain relief. Form drip loops to divert water away from terminals, and apply manufacturer torque values to glands and terminal screws to maintain seals and contact pressure. Leave adequate internal clearance for wiring and future additions to minimize invasive rework.

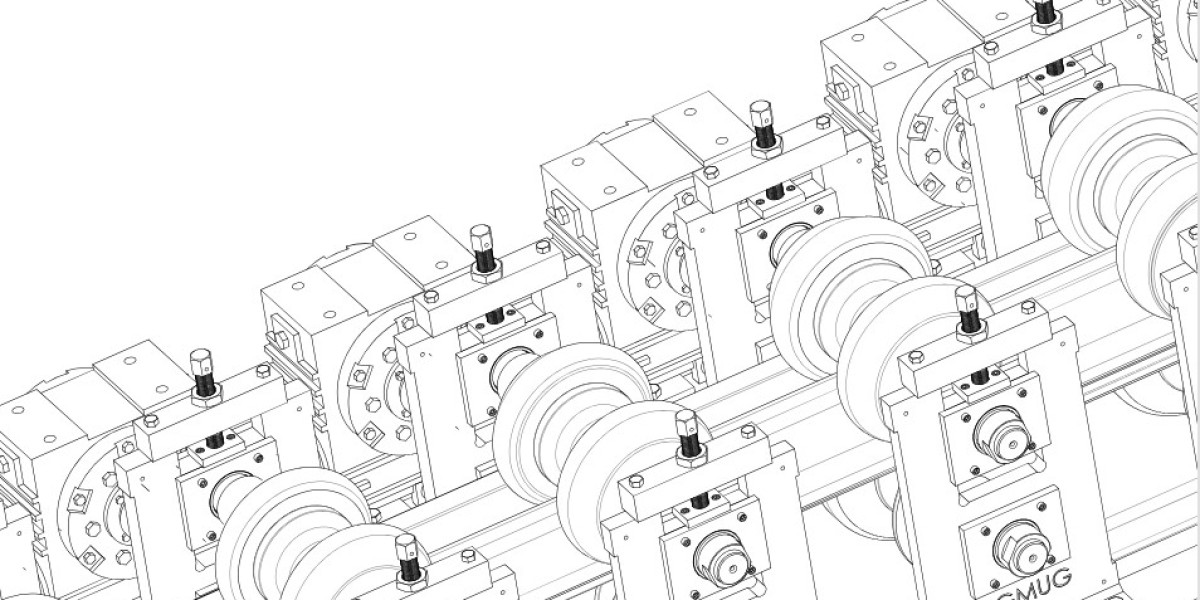

Nante Accessory Ecosystem and Modular Options

Choosing a supplier that offers a compatible accessory range simplifies procurement and fieldwork. Modular DIN-rail frames, plug-in protection modules, pre-cut gland plates, and dust caps reduce on-site assembly and speed repairs. Standardized mounting footprints and interchangeable inserts allow upgrades without full enclosure replacement, and service kits for common wear items—gaskets, gland seals, and replacement handles—help maintenance teams react quickly to site issues.

Thermal planning, internal layout, and ventilation

Heat management is a hidden reliability factor. Group high-current devices away from sensitive electronics and provide natural convection paths where possible. Passive thermal strategies—spacer mounts, heat-dissipating plates, and strategic component placement—are preferred for outdoor enclosures because they avoid added failure points. If active cooling is required, choose filtered fans and plan filter replacement intervals as part of routine maintenance to preserve ingress protection.

Wiring, labeling, and safety best practices

Clear labeling and logical wiring paths speed troubleshooting and reduce human error. Separate power and control wiring to minimize electromagnetic interference and allow technicians to isolate circuits safely. Provide accessible bonding points and ensure continuous grounding paths to meet local electrical codes. Where unauthorized access is a concern, include lockable handles or tamper-resistant hardware to protect against accidental contact or malicious interference.

Maintenance schedules and lifecycle cost control

Proactive maintenance reduces lifecycle costs. Inspect gasket condition, fastener torque, hinge operation, and gland integrity on a regular schedule suited to the environment—frequent checks in corrosive settings, longer intervals in benign ones. Replace consumables before failure, and keep a compact spare-parts kit onsite to minimize downtime. Track maintenance activities to identify recurring issues that may indicate a need for upgraded materials or revised installation methods.

Procurement tips and documentation to request

When procuring enclosures, require independent test reports for IP ratings, material certificates, and production inspection records. Ask for CAD cutouts and clearances early to resolve cable entry conflicts in design phase. Favor suppliers who provide accessory lists, service kits, and modular options so long-term spare logistics are simplified. A slightly higher initial cost for a properly rated enclosure will often result in lower total cost of ownership through fewer replacements and less reactive maintenance.

Specifying the right outlet housing combines attention to sealing, materials, layout, and maintainability. Prioritize enclosures with proven field performance, modular accessories, and clear documentation to ensure reliable power access and straightforward upkeep across the installation lifetime. For model guidance, installation resources, and spare-parts support, visit www.nante.com