Gusu Candy Bar Line production consistency is closely tied to how well each processing stage works together rather than the speed of any single operation. In modern energy bar manufacturing, consistency refers to stable portioning, uniform shape, and predictable texture across repeated batches. These outcomes depend on coordinated mechanical performance, controlled material flow, and reliable process timing.

One key factor affecting consistency is how raw materials are handled before forming. Energy bar mixtures often vary in density, moisture, and ingredient distribution. A production line designed to manage these variations helps ensure that the mixture enters the forming stage evenly. When material flow remains steady, downstream processes operate under predictable conditions, reducing fluctuations in final output.

Forming and shaping stages also influence uniformity. Consistent pressure application and stable mold alignment help create bars with similar dimensions from batch to batch. When forming components maintain steady contact and movement patterns, the line produces energy bars that align with packaging and cutting requirements without frequent adjustment.

Cutting accuracy is another important consideration. Clean, repeatable cutting actions help ensure each bar meets expected size standards. When cutting intervals and blade positioning remain stable, waste is reduced and downstream handling becomes more efficient. This supports smoother packaging operations and minimizes manual correction during production.

Temperature control across the line contributes to predictable results as well. Energy bar formulations can respond differently to heat depending on ingredients such as syrups, proteins, or inclusions. Production systems that support steady thermal conditions help maintain consistent texture during forming and cooling stages. This reduces variation that might otherwise appear between early and later production runs.

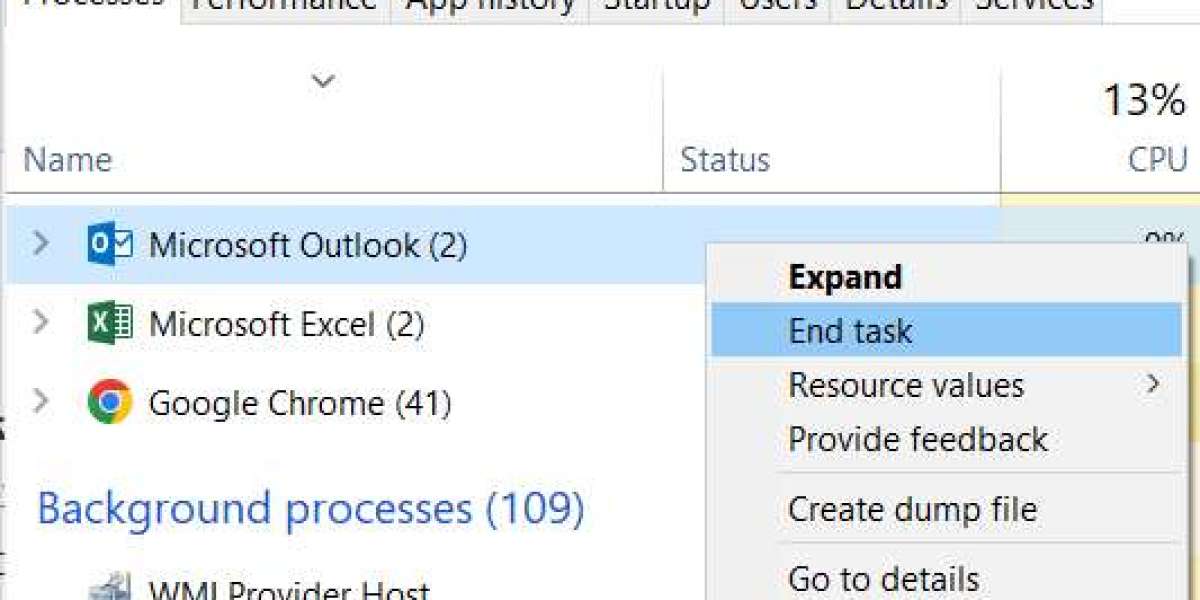

Automation coordination plays a role in long-term stability. When feeding, forming, cutting, and conveying systems operate in sync, production rhythm remains steady. This coordination helps operators manage output planning more effectively while reducing sudden changes that can affect bar appearance or weight.

Flexibility is also relevant to consistency. Production lines often need to accommodate multiple formulas or bar sizes without disrupting output quality. Equipment designed with adjustable parameters allows manufacturers to adapt while maintaining predictable results. This balance supports both operational efficiency and product reliability.

From a manufacturing perspective, consistency supports brand reliability and supply planning. Stable production reduces rework, limits downtime, and helps maintain delivery schedules. These operational benefits make consistency a key focus when evaluating energy bar production equipment.

Gusumachinery develops solutions that emphasize coordinated processing, stable control, and adaptable production layouts. By focusing on how each stage contributes to overall output stability, the equipment supports manufacturers aiming for repeatable results across long-term operations.

For further industry insights related to energy bar production systems, reference materials are available at https://www.gusumachinery.com/news/industry-news/are-energy-bar-lines-really-effective-and-efficient.html