The world of manufacturing today is extremely specialized and therefore the solutions can no longer be generic. Industries are also requiring parts which have a precise specification, which will work in sophisticated systems, and which are capable of working in rigorous conditions. The change has led to a major expansion of custom profile extrusion, a production technique which allows the production of accurately shaped plastic profiles to meet each application.

The practice of extrusion of custom profiles has become a significant solution to manufacturers who need flexibility, efficiency and innovation. This process can be used in industries that require specific control of shape, material and performance characteristics such as construction and automotive, as well as medical, electronic and industrial equipment manufacturing. Its flexibility makes it a pillar of the present-day custom manufacturing strategies.

Learning the Basics of Profile Extrusion

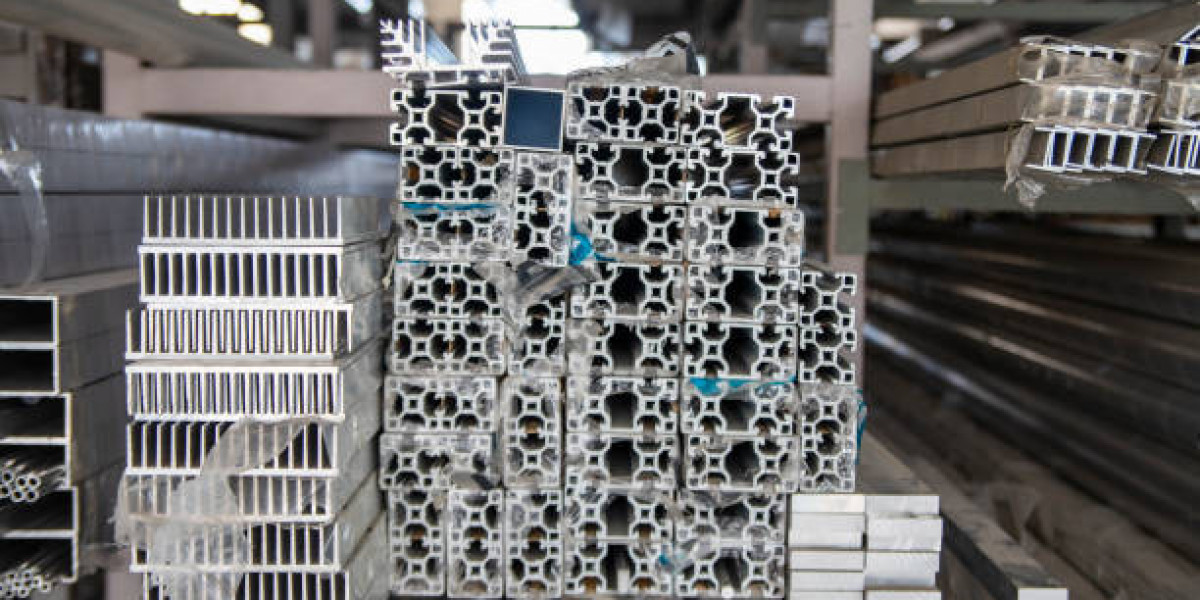

Profile extrusion is a continuous process of manufacturing where molten plastic is forced through a die to form a particular cross-sectional shape. As compared to injection molding that involves the production of discrete parts, extrusion is used to produce long continuous profiles that can be cut to length when required. When this is made customized it becomes a potent producing tool of highly specialized components.

Custom profile extrusion enables manufacturers to create cross-sectional geometries of a different kind which cannot be achieved with standard profiles. This feature allows the making of seals, channels, trims, frames, guides, and structural components that are accurate to precise functional specifications. What is obtained is a part that is perfectly adapted to its use, and requiring no additional operations or assembly.

The importance of Customization in Profile Extrusion

The distinguishing benefit of individual profile extrusion is customization. Each application possesses distinct requirements in regard to size, shape, and flexibility, strength and environmental exposure. Normal extrusions can be used to reasonably match these requirements but tailor-made solutions are used to guarantee optimal functionality and integration.

Through ground-up design, manufacturers are able to remove or reduce unwarranted material, enhance functionality as well as product aesthetics. Custom profile extrusion facilitates innovation as the designers are not required to alter designs to fit profile but concentrate on performance of the design. It is this liberation which results in superior products and more efficient ways of production.

Engineering Involvement in Custom Profile Extrusion

Successful extrusion of the custom profile requires engineering expertise. Projects are initiated with a thorough analysis of the application application, load requirements, environmental, tolerances and ways it is to be installed. Engineers collaborate in order to turn functional requirements into accurate profile designs.

The flow of material, design of the die and cooling character should be taken into consideration to achieve dimensional stability and quality stability. Engineers also consider the profile cutting, assembling, or finishing which also makes sure that the extrusion process helps in the subsequent manufacturing processes. Such a teamwork approach reduces the risk and assures of making the final product perform as per the expectation.

Selection and Performance Optimization of Materials

The material selection is a very important aspect of custom profile extrusion. There exist different plastics with different degrees of flexibility, rigidity, chemical resistance, UV stability and thermal performance. The choice of material is the key to long-term functionality and durability.

Custom profile extrusion has been found to support most of the thermoplastic materials enabling the manufacturers to create performance characteristics to particular environments. Depending on whether a profile needs to be resistant to outdoor environment or repeated movement, or come into contact with chemicals, material choice is selected at the point of optimizing performance, cost and manufacturability. This customized solution will guarantee quality performances over the product life cycle.

Accuracy of Tools and Die Making

The core of the custom profile extrusion is the extrusion die. The shape, consistency, and surface quality of the final profile depends on the design of the die. Machining of precision tools is required in order to have a constant flow of material run at equal dimensions when doing lengthy production lines.

Tailor made dies are designed taking into consideration the material shrinkage, temperature fluctuations, and flow characteristics. Correct design of die reduces the defects like warping or irregular thickness. Investment in the high-quality tooling will provide the manufacturers with repeatable results with custom profile extrusion and long-term efficiency.

Efficiency in Production and On-going Production

Efficiency of custom profile extrusion is among the major benefits. Since extrusion is a continuous process, it is suitable in production of long profiles in large quantities. This efficiency is accomplished to produce low per-unit costs and uniform production even in complicated shapes.

In-line processing can also be done using custom profile extrusion, including cutting, drilling, co-extrusion, etc., thus eliminating the requirement to do other operations. These efficiencies simplify production and reduce lead-time, which enables extrusion to be an appealing solution to high-volume and specialized manufacturing requirements.

Flexibility in Design and complicated Geometries

High design flexibility is provided by custom profile extrusion. Profiles may be designed with sophisticated cross-sections, multi-cavity or incorporated functional attributes. This feature enables the manufacturer to make multiple functions one profile, which minimizes the number of parts and complexity of the assembly.

Co-extrusion also makes it more flexible as it allows using several different materials in one profile. Under this method, various portions of the profile may have varied characteristics, e.g. one part may be rigid and the other flexible. This freedom of design facilitates innovative solutions to problems that would be hard or expensive to come up with with other production techniques.

Quality Management and Uniformity

Tolerance in extrusion is very important especially in assemblies where profiles are needed and tight tolerance is needed. Custom profile extrusion depends on the accuracy of the processes in order to retain dimensional accuracy and quality on the surface during the production.

The quality control is incorporated throughout the process, starting with the inspection of the materials and ending with the profile measurement. The monitoring helps in keeping track of the profiles and ensuring that they are operating as desired and specifications are met. This quality focus saves time on wastage, increases reliability and customer trust in the end product.

Economy of Scale by personalization

Custom solutions are commonly viewed as more costly to obtain, but custom profile extrusion can often be seen to provide cost benefits in the long-run. Manufacturers cut the waste and minimize the costs of production through streamlining of the material and removal of unnecessary features. There is also reduced requirement of extra parts or assembly steps to create custom profiles which increases the cost effectiveness.

The design features can be tailored to the exact specification of an application and typically lead to lower service life and lower maintenance needs. These are some of the reasons why the composite profile extrusion is a great investment in most industries.

Bearing Industry-Specific Applications

Custom profile extrusion has many industries and their needs are different. Extruded profiles are used in construction to offer weather resistant seals and structural elements. They are used in automotive design in order to promote lightweight designs and reduction in noise. Insulation, Protection and functional integration of electronics and medical industries use specialized profiles.

These different applications are accommodated by custom profile extrusion through the adaptation of materials, designs and processes. Special competencies in the industry also guarantee that the profiles are of regulatory, performance and aesthetic standards.

Sustainability and Responsible Manufacturing

The concept of sustainability is becoming a factor that is very pertinent in the manufacturing process. Custom profile extrusion helps in practicing sustainability so that it can use the material properly and minimizes the waste. The profiles may be made to use the material of performance in the minimum quantity, reducing wastage.

Numerous extrusion operations are also in support of recyclable materials and energy-saving production processes. By matching the custom profile extrusion to the sustainability objectives, the manufacturers can minimize the impact on the environment and keep the high-performance standards.

Long-term Cooperations and Partnerships

The extrusion of custom profiles is often successful and developed on the basis of long-term relationships. Close communication between manufacturers and extrusion suppliers creates trust and innovation as well as continuous improvement. With time, better understanding of application requirements and more effective processes of developing them are reached through these relationships.

In the long term, the cooperation also helps keep the product evolving to enable the product profiles to be improved as demand shifts. Such flexibility guarantees that custom profile extrusion is a useful manufacturing application throughout the product life cycle.

Future of Custom Profile Extrusion

Technological progression and increasing need to have a custom profile extrusion are the drivers to the future of custom profile extrusion. The field of extrusion manufacturing is becoming larger because of advances in digital design tools, automation, and material science.

With the industry still on the path of focusing on customization, efficiency and sustainability, custom profile extrusion will gain more relevance. Its capability to provide application-specific solutions precisely makes it one of the central technologies in manufacturing of the next generation.

Conclusion: Accuracy and Versatility With Custom Profile Extrusion

Custom profile extrusion is an effective production tool which allows accuracy, efficiency and creativity. It provides industries with greater requirements than standard components by providing unmatched design flexibility and performance optimization.

Custom profile extrusion offers cost-effective solutions through engineering teamwork, material expertise, and process control to provide reliable solutions to particular applications. With the manufacturing process as a constantly shifting phenomenon, this adaptable process will continue to be an important instrument of businesses that need to gain a competitive edge and achieve success in the long-term.