The manufacturing focus of EI Transformer Factory at Nbcbdz is closely tied to the steady rise of adaptable electrical systems used across varied industries. As device requirements shift toward tighter spatial layouts and consistent thermal behavior, the processes behind compact magnetic components have grown more noticeable. Understanding how these parts are shaped, wound, and prepared helps designers make choices that fit voltage, isolation, and endurance expectations. With each development step, from lamination planning to winding configuration, the goal remains alignment with practical operating conditions rather than pursuit of abstract design ideals. This foundation supports engineers who need precise coordination between physical form and electrical behavior without unnecessary complexity.

Across many fields, engineers look for components that maintain stable operation within expected tolerances. Transformer construction plays a distinct role here because small differences in winding density, insulation layering, or lamination treatment can influence long-term behavior. Production teams often focus on straightforward manufacturing paths that maintain consistency without pushing dimensions to extremes. This helps avoid sudden changes in inductance or heat spread. When components are applied in environments with frequent duty-cycle variation, predictable magnetic behavior becomes even more important. Reliable fit and form allow equipment builders to reduce adjustment cycles during assembly, keeping integration processes smoother.

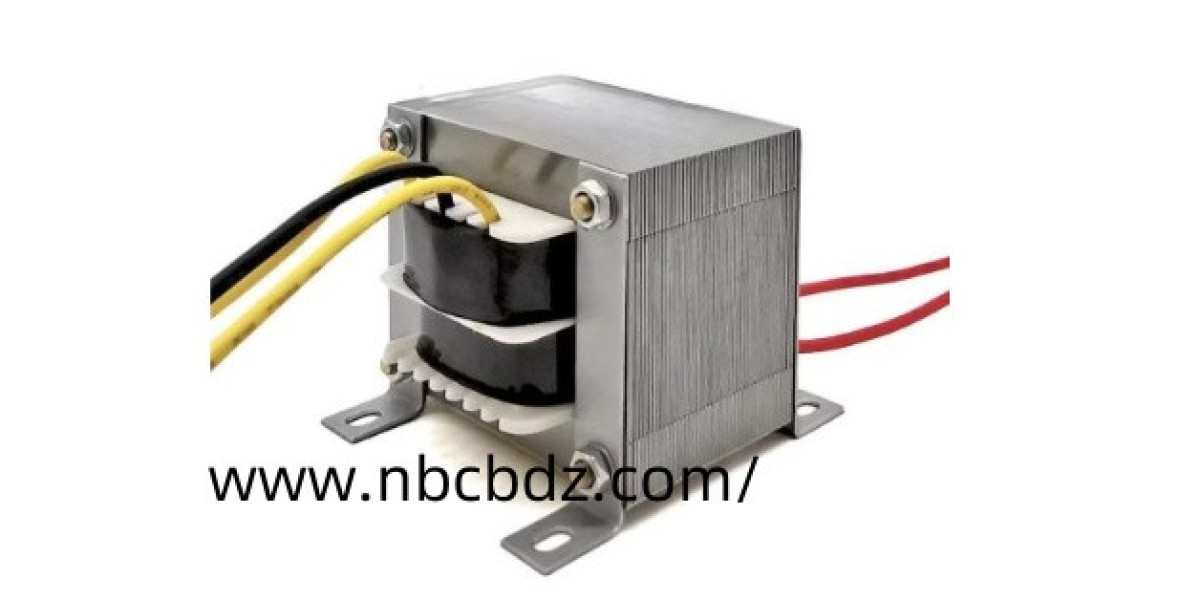

The structure of EI-type magnetic parts gives system planners a practical balance between footprint and thermal flow. Laminations arranged in controlled patterns help guide magnetic flux while managing vibration and noise. For devices that must operate for extended periods, this balance can provide a dependable performance window. Practical material treatments also help maintain surface stability, supporting a steady heat path between core and windings. While each application differs, the expectation of consistent operation under ordinary electrical loads encourages careful alignment between core geometry and winding technique. This approach reduces variability that might complicate maintenance or inspections later in the product's life.

For engineers prioritizing straightforward installation and predictable field behavior, attention often shifts toward assembly factors such as terminal arrangement, mounting clearances, and connector durability. These aspects rarely receive attention in general discussions, yet they influence how easily equipment can be serviced. Clear marking, clean winding layout, and steady connection points help technicians track behavior and diagnose issues without lengthy disassembly. Such practical considerations support stable equipment operation and reduce unnecessary downtime. As power systems expand to include more control segments, ensuring that individual magnetic components integrate without complication becomes increasingly important.

One of the continuing discussions around transformer selection involves balancing design tolerance with cost and operating expectations. Over-specified parts can add unwanted bulk, while under-specified ones may introduce performance drift. Practical production approaches support a middle ground where materials, dimensions, and insulation align with real-world requirements. This mindset helps avoid unnecessary strain on connected circuits and reduces the likelihood of changes during prototype testing. By focusing on stable design boundaries, engineers can maintain predictable performance across varying environmental conditions and avoid extended tuning cycles during late-stage integration.

If you want to examine how practical transformer choices influence your projects, consider visiting https://www.nbcbdz.com/product/ . Look through the details, trace how each step fits your planning needs, and let curiosity guide your next click.