Modern jewelry customers expect flawless finishing, intricate details, and long-lasting durability. These expectations have pushed businesses to adopt tools that maintain quality without slowing down the workflow. This shift in standards is the reason many jewelers rely on the jewellery laser welding machine as a core part of their daily operations. From small studios to large manufacturing units, this machine supports high-level craftsmanship while protecting delicate materials.

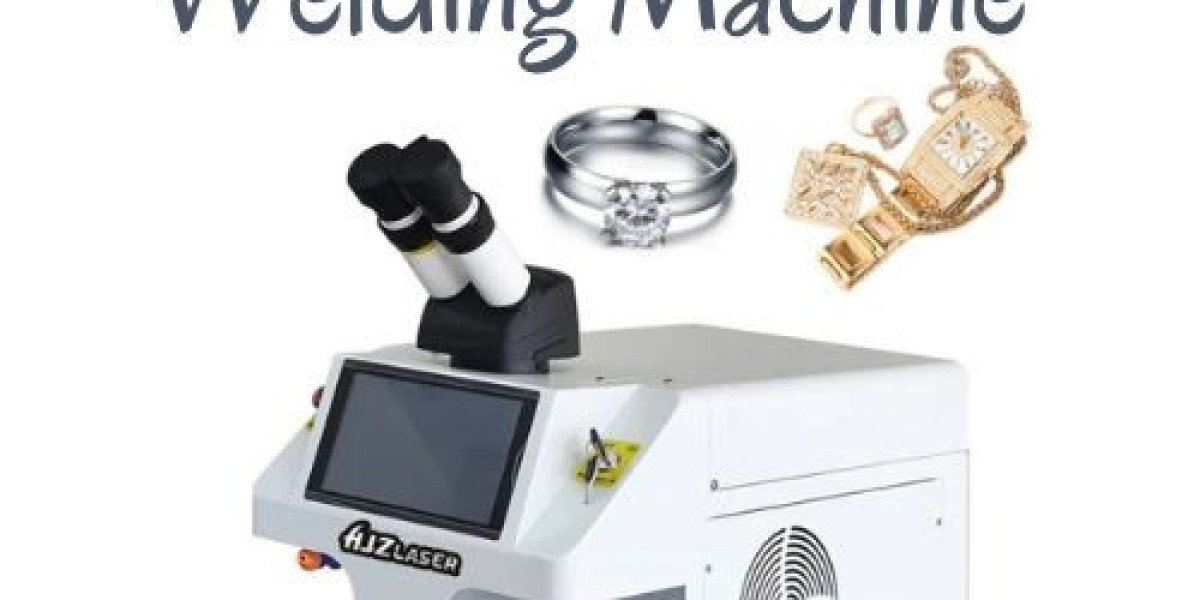

Jewelry pieces such as rings, earrings, pendants, chains, bangles, and luxury watches often involve working with incredibly fine joints. Traditional heating methods can distort these details, causing unwanted marks or changing the structural integrity of the material. The jewellery laser welding machine helps overcome such challenges by applying a narrow and controlled heat source. The weld area remains focused, preventing unnecessary impact on surrounding surfaces and gemstones.

Another important factor in jewelry production is material diversity. Workshops often work with gold, silver, platinum, stainless steel, titanium, and other alloys. Each material responds differently to heat. Some metals become soft too quickly while others require exact temperatures to bond correctly. The jewellery laser welding machine makes it easier to handle these variations because it provides stable and predictable performance. The jeweler can control intensity, duration, and energy specifically for the project at hand.

For repair specialists, this machine has changed the way delicate jewelry restoration is performed. Broken prongs, cracked rings, worn-out links, and loosened settings can be fixed without removing stones or exposing them to high heat. Many gemstones are extremely sensitive—especially emeralds, opals, pearls, and certain treated stones. Using traditional soldering on them risks damage. The jewellery laser welding machine minimizes such risks because its heat is localized, allowing the jeweler to repair complex pieces while keeping gemstones safe.

In custom jewelry making, precision is everything. Designers often need to join small components, attach decorative elements, or create detailed patterns with fine metal. These tasks require exact control. The jewellery laser welding machine supports such work by offering a precise and consistent welding point that reacts instantly to the jeweler’s adjustments. This capability allows artisans to bring imaginative designs to life without being limited by the constraints of manual processes.

Time is also a major element of jewelry production. Customers expect quick delivery, especially in busy seasons. Workshops using the jewellery laser welding machine often experience faster project completion because they no longer depend on slow heating cycles or repeated cleanups. The weld typically leaves a smooth surface that requires minimal polishing. This saves hours of work during busy days, enabling jewelers to serve more clients while maintaining quality.

Another growing trend in the jewelry industry is personalized design. Customers want unique pieces that match their preferences. To meet such expectations, jewelers need tools that support small adjustments, precise modifications, and clean finishing. The jewellery laser welding machine makes this easier because it allows jewelers to add tiny components, adjust shapes, strengthen joints, and refine details without affecting the rest of the piece. This precision helps businesses offer personalized work that stands out in competitive markets.

Jewelry manufacturing also involves dealing with thin metals and lightweight structures. Traditional flame techniques can cause melting or bending if the jeweler does not maintain perfect control. The jewellery laser welding machine offers consistency that reduces these risks. Its targeted heat helps preserve the original dimensions of the jewelry piece while achieving a strong and clean weld. This stability is especially important when dealing with hollow jewelry or micro-components.

In many workshops, safety and cleanliness are priorities. Open flames and chemical fumes from soldering can create an uncomfortable working environment. The jewellery laser welding machine operates without such complications. It provides a cleaner workspace and a controlled welding zone, making it easier to maintain a stable environment. This benefits the jeweler and also ensures the jewelry stays free from unwanted residues during the crafting process.

The growth of online jewelry businesses has increased the demand for high-quality finishing. Customers compare products quickly using detailed images and videos. Even a small imperfection can affect their purchasing decision. With a jewellery laser welding machine, jewelers can produce consistent finishing across their entire product range. This consistency helps build trust with customers and enhances the reputation of the brand.

Workshops that handle high-value jewelry pieces also appreciate the reliability this machine brings. When repairing luxury items such as antique rings or branded watches, jewelers must work without error. A small mistake can significantly reduce the value of the item. The jewellery laser welding machine helps protect the original character of these pieces by enabling accurate and controlled repair work.

Another important factor in the jewelry industry is material wastage. Precious metals are expensive, and jewelers aim to minimize loss as much as possible. Traditional methods often lead to melting, dripping, or unwanted residue. The jewellery laser welding machine reduces this wastage because it works with exact targeting. The jeweler can join metals with minimal material use, helping maintain profitability while reducing scrap.

Training new artisans is also simpler with this machine. Traditional soldering requires long practice to control heat and flame. The jewellery laser welding machine offers a more predictable learning experience. New jewelers can gradually improve their skills because the machine allows for controlled and stable operation. This helps workshops grow their workforce more efficiently and keep production running smoothly.

Jewelry businesses that want to expand their services often choose this machine because it supports multiple tasks. It handles repairs, manufacturing, design modification, vintage restoration, micro-welding, and even advanced customization. This versatility allows workshops to offer more services and attract customers with diverse needs.

Many jewelry professionals describe the jewellery laser welding machine as a long-term investment because it improves workflow and quality over time. By replacing older tools, workshops increase their accuracy and reduce time spent on post-weld cleanup. This improvement helps build stronger customer relationships and repeat business.

In addition to daily use, the machine also supports experimental techniques. Some designers use it to explore complex patterns, build intricate framework designs, or merge unconventional materials. The jewellery laser welding machine gives them the freedom to innovate without being limited by heat inconsistency or manual precision concerns.

As the global jewelry market continues to grow, artisans are focusing on durability and fine workmanship. Customers purchasing engagement rings, luxury sets, and custom pieces want assurance that their jewelry will last for years. The jewellery laser welding machine allows jewelers to strengthen joints, reinforce weak areas, and create clean connections that support long-term durability.

Jewelry production also involves dealing with surface finishing. A clean weld means less polishing, which saves time and preserves the metal’s shape. The jewellery laser welding machine contributes to this process by producing smooth joining points. This results in consistent shine and clean lines across the final product.

Workshops that invest in this machine often notice improved efficiency. Tasks that once required multiple steps can now be done more quickly with better results. This efficiency allows jewelers to expand their production capabilities and meet tight deadlines without compromising quality.

Final Thoughts

The jewellery laser welding machine has become a fundamental tool for modern jewelry crafting. Its ability to deliver accuracy, protect delicate materials, and support detailed design work makes it essential for workshops of all sizes. With its reliable performance and consistent results, it helps jewelers meet customer expectations, enhance craftsmanship, and stay competitive in today’s fast-evolving jewelry market.