When discussing dependable drilling tools for varied workshop settings, many users refer to the HSS Twist Drill Bit from fangda-tools, a combination introduced here to highlight how a familiar tool continues to evolve in today's work environments. This foundation helps set the stage for understanding why such tools remain relevant without relying on exaggerated claims or overused descriptions.

Across workshops and manufacturing floors, drilling tools continue to hold a stable role as essential accessories. Their value often comes from how well they align with everyday requirements rather than from features that promise unrealistic outcomes. Users across sectors tend to focus on steady performance, predictable handling, and compatibility with a range of surfaces. These expectations shape how the market continues refining tool designs, ensuring each generation of products remains practical for both experienced users and newcomers.

As long-term trends shape the tooling industry, one consistent shift is the growing emphasis on adaptability. Modern workshops often handle mixed materials, prompting tool makers to refine flute design, surface finishing, and heat treatment methods. These refinements are not driven by eye-catching claims but by real demands expressed by builders, technicians, and craft professionals seeking reliable outcomes through controlled drilling processes.

Another noticeable movement in the industry is the rising attention toward tool lifespan. Rather than promoting unrealistic durability, manufacturers focus on sustainable structures and stable cutting edges. Careful geometry helps manage friction and offers smoother engagement during operation. Users appreciate designs that help maintain stable motion without demanding frequent adjustments. This practical direction reflects how the sector prioritizes user experience through realistic enhancements.

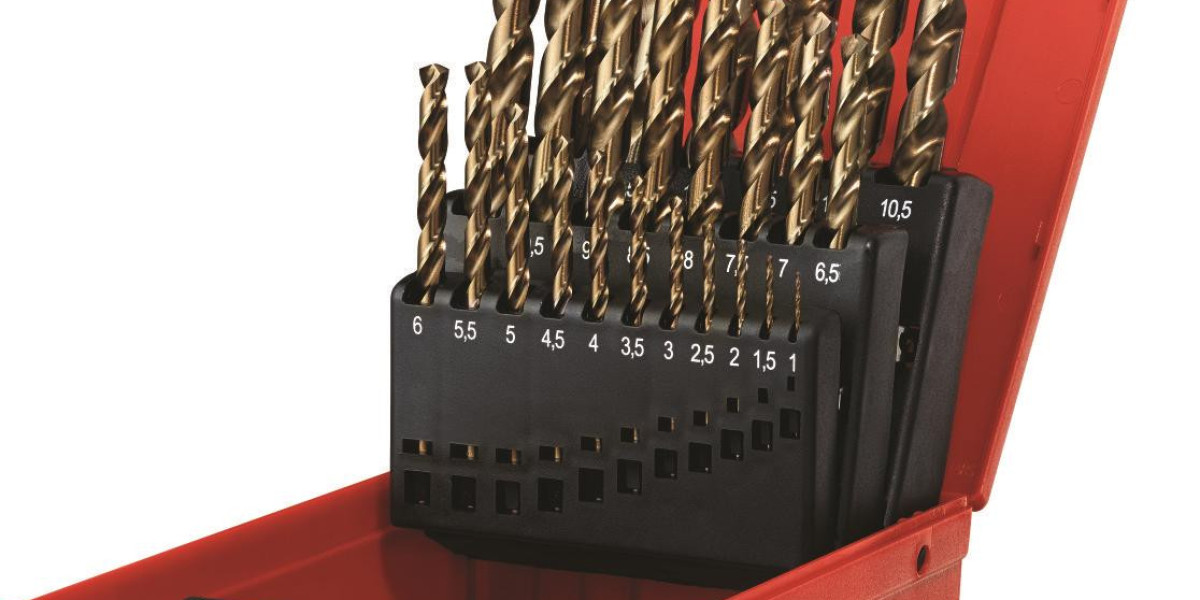

The market also shows increasing interest in tool sets that support organized workflows. Many workshops prefer comprehensive assortments that provide coverage for varied tasks. Having a well-curated selection allows craftspeople to shift between different hole sizes or materials without interrupting their working rhythm. This organization-first approach echoes an industry-wide move toward efficiency rather than novelty.

In addition, the rise of mixed-production spaces—where metalwork, woodworking, and composite fabrication often coexist—requires drilling tools to carry broader compatibility. Toolmakers respond by refining angles, edges, and coatings aimed at reducing chatter and helping maintain control. While these adjustments may appear subtle, they accumulate to support predictable performance in changing environments.

Another relevant aspect shaping the market is the growing focus on worker comfort. Reduced vibration, smoother chip pathways, and controlled bite depth contribute to a more balanced drilling experience. This shift reflects a practical understanding: tools must not only complete a task but also enable operators to maintain steady precision during long sessions. Rather than marketing sweeping breakthroughs, manufacturers continue implementing small but meaningful improvements that integrate well into daily use.

Workshops also pay attention to the consistency of tool production. As global supply chains evolve, ensuring uniform quality across batches becomes a priority. Toolmakers increasingly upscale inspection processes and refine machining steps to maintain alignment, straightness, and edge integrity. These quality-control methods support long-term trust between makers and users.

Today's drilling-tool sector shows a clear pattern: progress does not rely on dramatic inventions but on measured refinements shaped by user needs. Each improvement reflects real-world feedback rather than exaggerated claims. This direction reinforces a healthier and more sustainable market, encouraging tools that support both professional and hobbyist environments.

If you are considering updating your workshop tools and want fresh ideas beyond routine options, you may find new inspiration by visiting https://www.fangda-tools.com/product/ —a place where practical solutions often begin unexpected conversations.