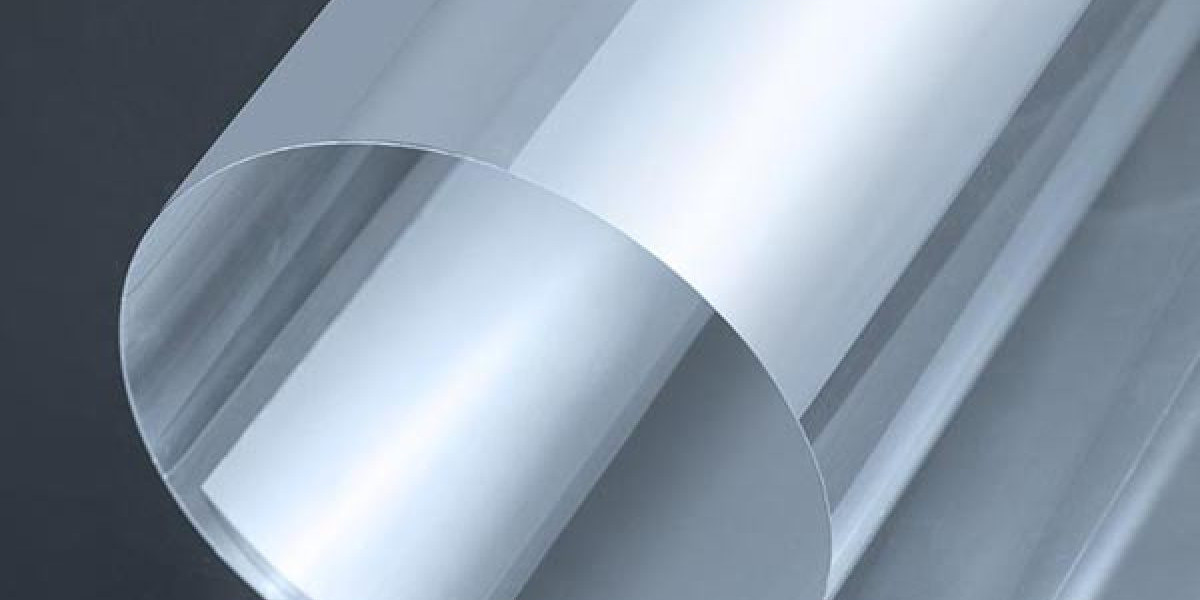

PETG Film is quickly becoming one of the most versatile materials used across numerous industries due to its exceptional properties such as clarity, strength, and ease of processing. From packaging to healthcare, automotive, and electronics, it is a material that bridges the gap between performance and sustainability. Its unique combination of features makes it the go-to material for businesses seeking a flexible, durable, and environmentally responsible solution. In this article, we will explore the diverse applications of PETG and its impact on different sectors.

In the packaging industry, PETG Film has revolutionized the way products are displayed and protected. Its crystal-clear appearance makes it an ideal material for retail packaging where visual appeal is essential. This is particularly important in the packaging of consumer goods such as cosmetics, beverages, and electronics. PETG’s high clarity ensures that the contents are easily visible, enhancing product presentation while also providing a strong, protective barrier. The material’s resistance to impact and cracking makes it an excellent choice for products that require long shelf life and durable, tamper-evident packaging.

Another significant application for PETG is in the creation of blister packs. These packs are commonly used for pharmaceuticals, consumer goods, and electronics. PETG’s clarity allows for easy inspection of the product inside, while its resistance to sterilization processes such as gamma radiation makes it ideal for use in medical device packaging. It is also a popular material for food packaging, where safety, freshness, and visual appeal are key considerations. PETG films are not only food-safe but also possess a high degree of chemical resistance, ensuring the preservation of food quality even in challenging storage conditions.

In the healthcare and medical industries, PETG is widely used in the manufacturing of various medical components, such as protective covers, sterilization wraps, and diagnostic device housings. The material’s strength and ability to withstand sterilization processes without compromising integrity make it ideal for these applications. PETG is also commonly used for surgical trays and diagnostic packaging. The non-toxic nature of PETG and its ability to meet regulatory standards such as FDA compliance make it a trusted material in this field.

PETG also has a growing presence in the automotive industry. In vehicle interiors, it is used to create clear protective covers for various components, including dashboard parts, light covers, and trim pieces. Its durability and resistance to environmental factors like UV rays, moisture, and temperature fluctuations make it an ideal material for automotive applications. PETG is also used for making interior display panels and functional parts that require a high level of impact resistance. Its ability to be molded into intricate shapes makes it a versatile material for creating both aesthetic and functional automotive components.

Another emerging application for PETG is in the field of signage and displays. Due to its high clarity and ease of printing, it is used to create high-quality signage for retail stores, exhibitions, and trade shows. The material’s ability to be thermoformed and cut into precise shapes allows for the creation of intricate and custom designs, making it a preferred choice for point-of-sale displays and backlit signage. Additionally, PETG’s impact resistance ensures that signs are durable and can withstand the wear and tear of high-traffic environments.

In the electronics industry, PETG is used in the production of clear protective covers and packaging for electronic devices such as smartphones, laptops, and home appliances. Its ability to resist impact and provide a clear view of the product makes it ideal for electronic product packaging. PETG’s excellent thermoformability allows it to be shaped to fit complex product designs, while its recyclability ensures that companies can meet their sustainability goals by using an eco-friendly packaging material.

Shanghai Ming Shida International Trading Co. has become a trusted supplier of high-quality PETG films, providing solutions for a range of industries including packaging, healthcare, automotive, and electronics. With a focus on durability, clarity, and sustainability, the company offers tailored material solutions to meet the specific needs of each sector. To learn more about their PETG-based products and how they support businesses with top-tier materials, visit https://www.shanghaimsd.com/ .