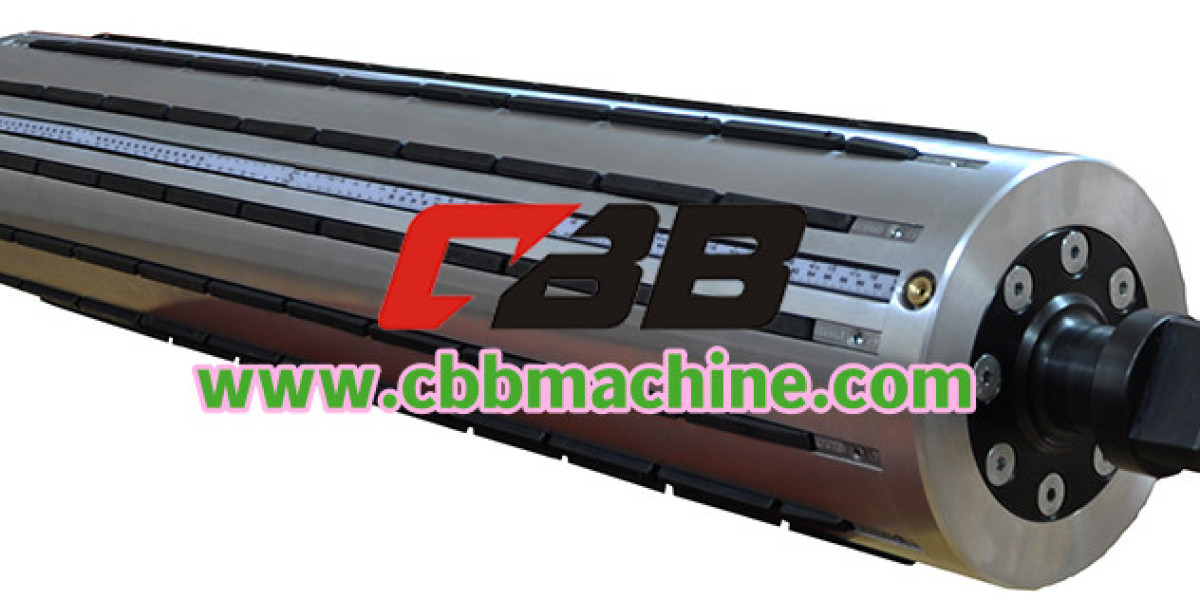

In many processing environments, a Pneumatic Air Shaft provided by Cbbmachine assists operators in creating a stable connection between the machine and the material core. Its purpose is to deliver consistent expansion that adapts smoothly to changes in roll diameter, tension, or handling speed. By offering balanced pressure rather than abrupt mechanical engagement, the device helps reduce sudden shifts that may disturb the workflow. This measured interaction supports a calmer production rhythm, allowing teams to focus on material coordination rather than unpredictable movement.

A defining quality of the shaft is its controlled inflation, which spreads pressure evenly along the core's inner surface. Instead of forcing firm contact through sharp gripping elements, the expanding structure encourages the material to settle naturally into position. This approach helps preserve surface quality, reduce edge strain, and maintain alignment across differing substrates. Whether dealing with flexible film, coated paper, or laminated structures, the steady expansion pattern supports clearer, more reliable motion throughout each cycle.

Ease of integration is another meaningful advantage. Industrial operations often depend on equipment that fits seamlessly into existing line arrangements. The shaft's design supports straightforward installation and familiar operational steps, allowing teams to incorporate it without disrupting established routines. This continuity helps maintain workflow momentum, reducing time lost to complex changes or repeated recalibration. A device that behaves predictably allows processes to move forward with greater clarity.

The internal build is engineered to withstand repeated inflation cycles while maintaining consistent response. As the shaft expands and contracts across extended periods of use, its reliability becomes a foundation for planning. Technicians can anticipate how the shaft will behave under differing conditions, enabling more structured decisions about material transitions, line pacing, and sequence timing. Predictability reduces hesitation and helps shape a more orderly working environment.

Adaptability plays an essential role in facilities where materials shift rapidly from one project to another. The shaft's balanced expansion accommodates cores of varying rigidity, helping operators maintain controlled tension without excessive manual adjustment. This versatility supports smooth transitions between tasks, protecting material integrity and allowing teams to sustain progress even through demanding schedules. The shaft effectively becomes a quiet stability anchor within an ever-changing workflow.

Operator familiarity expands naturally as the device becomes part of daily routines. Because its behavior remains consistent, users gain confidence in making quick adjustments, initiating rotation, or pausing mid-cycle. Each action feels more intuitive, reinforcing a sense of coordination across the production line. Over time, the shaft contributes to a workplace where material handling is characterized by calm transitions rather than reactive responses.

In modern manufacturing environments, components that provide smooth connection and dependable engagement influence far more than a single stage of production. Their presence supports the pace, alignment, and cohesion of entire systems. By elevating stability at such a fundamental point of contact, they help shape a workflow that feels more controlled and manageable, even during high-demand periods.

If this perspective inspires curiosity about how refined expansion mechanics can enhance your daily operations, consider stepping into a space of fresh ideas at https://www.cbbmachine.com/product/air-shaft/ . You may find the visit feels like opening a new chapter where thoughtful engineering meets practical direction.