Introduction to Raceway Cable Trays and Their Importance

In today’s fast-moving industrial and commercial world, power and data cables are the silent force that keeps everything running. From manufacturing machines and hospital equipment to servers and office networks, every critical system depends on reliable cabling. But without proper organization and support, these cables quickly turn into a tangled, unsafe, and inefficient mess. That’s where Raceway Cable Trays become essential.

Selecting the Best Raceway Cable Trays is not just about supporting wires—it’s about protecting your entire operation. The right choice improves safety, simplifies maintenance, enhances airflow, and prepares your facility for future expansion. On the other hand, poor-quality trays can lead to overheating, equipment failure, and costly downtime. This guide will walk you through every important detail you need to know to confidently select the right Raceway Cable Trays for your facility.

What Are Raceway Cable Trays?

Basic Definition

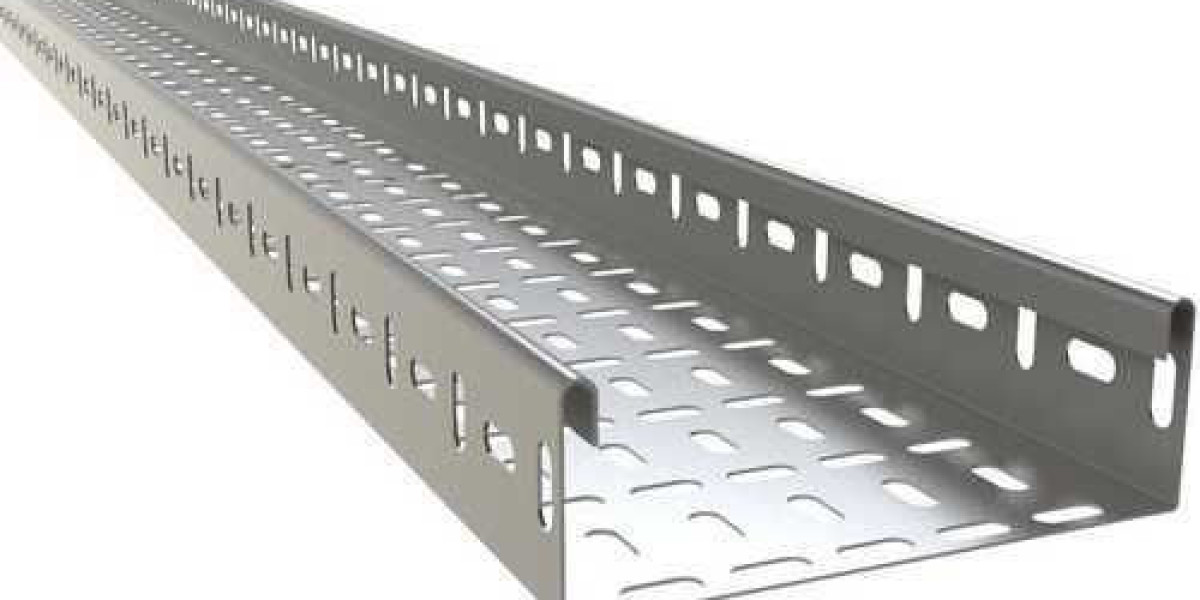

Raceway Cable Trays are structural systems designed to support, route, and protect electrical, communication, and control cables. They act as organized pathways that guide cables across ceilings, walls, and floors while keeping them accessible for inspection and maintenance.

Think of a cable tray as the backbone of your cable management system. Without it, cables are forced into tight conduits, laid loosely on floors, or tied randomly along structures—none of which are safe or efficient in the long run.

Role in Electrical Infrastructure

Raceway Cable Trays play a vital role in maintaining a clean, well-ventilated, and structured electrical infrastructure. They allow cables to dissipate heat more efficiently, reduce mechanical stress on wiring, and make future upgrades far easier. In short, they bring order and reliability to complex electrical systems.

Why Quality Matters in Raceway Cable Trays

Safety and Risk Reduction

Low-quality trays can bend, corrode, or collapse under load, putting both people and equipment at risk. Electrical fires, short circuits, and accidental cable damage often trace back to poor cable management. High-quality Raceway Cable Trays are engineered to handle heavy loads, resist corrosion, and meet strict safety standards, significantly reducing these risks.

Performance and System Reliability

Your entire electrical network relies on stable and secure cable routing. Weak or poorly installed trays can introduce sagging, vibration, and physical stress that shorten cable life. High-quality trays maintain consistent support, ensuring uninterrupted power and data flow across your facility.

Long-Term Cost Efficiency

At first glance, premium trays may seem more expensive. But when you consider reduced maintenance, fewer breakdowns, and longer service life, they offer superior value. The true cost of cheap trays often appears later in the form of lost production and frequent repairs.

Common Types of Raceway Cable Trays Used in Facilities

Ladder-Type Cable Trays

Ladder trays are the most widely used in industrial environments. Their open-rung design provides excellent ventilation and strong support for heavy power cables. They are ideal for long-distance runs where heat dissipation and mechanical strength are critical.

Solid Bottom Cable Trays

These trays offer full protection from dust, falling debris, and dripping liquids. They are often used where sensitive control or communication cables require extra shielding from the surrounding environment.

Wire Mesh Cable Trays

Wire mesh trays are lightweight, flexible, and easy to modify. They are commonly used in data centers and office buildings where frequent cable changes are expected and load requirements are moderate.

Channel Cable Trays

Channel trays are compact and suitable for short cable runs or low-voltage applications. They are often used for individual circuits or branch connections.

Key Factors to Consider Before Purchasing Raceway Cable Trays

Load-Bearing Capacity

Load capacity is one of the most critical factors in selecting Raceway Cable Trays. You must account for the combined weight of all present and future cables. Underestimating this can lead to tray deformation, sagging, or complete failure.

Environmental Conditions

The operating environment heavily influences tray selection. High humidity, chemical exposure, extreme temperatures, and vibration all demand specific materials and protective coatings.

Expansion and Flexibility

Facilities rarely remain static. Your cable tray system should be flexible enough to accommodate future expansions without requiring full replacement.

Corrosion Protection

Corrosion is a silent destroyer of metal trays. Proper galvanization, powder coating, or the use of non-metallic materials becomes essential in harsh environments.

Choosing the Right Material for Best Raceway Cable Trays

Steel Cable Trays

Steel trays offer outstanding mechanical strength and are ideal for heavy-duty industrial applications. When coated or galvanized, they also provide good corrosion resistance, making them a reliable choice for demanding environments.

Aluminum Cable Trays

Aluminum is naturally corrosion-resistant, lightweight, and easy to install. These trays are often used in commercial buildings, data centers, and locations where strength and corrosion resistance must be balanced.

FRP Cable Trays

Fiber Reinforced Plastic trays are highly resistant to moisture, chemicals, and salt-laden air. They are commonly used in chemical plants, wastewater facilities, and coastal installations where metal trays may deteriorate quickly.

Understanding Standards and Compliance for Cable Trays

Electrical Safety Codes

All Raceway Cable Trays must meet applicable electrical safety standards. These regulations ensure proper grounding, spacing, and mechanical strength to prevent electrical hazards.

Fire Safety Regulations

Fire-resistant trays and accessories help contain the spread of fire and protect critical wiring during emergencies. This is especially important in public buildings and healthcare facilities.

Quality Certifications

Certified products undergo rigorous testing for load capacity, durability, and safety. Certifications are a reliable indicator that the trays meet consistent manufacturing and performance standards.

Raceway Cable Trays for Different Facility Applications

Industrial and Manufacturing Facilities

Factories typically require heavy-duty trays capable of supporting thick power cables and resisting vibration, dust, oil, and temperature fluctuations.

Data Centers and IT Hubs

Data centers demand excellent airflow, lightweight designs, and frequent reconfiguration. Wire mesh and aluminum Raceway Cable Trays are commonly used for these environments.

Hospitals and Healthcare Buildings

Safety, fire resistance, and cleanliness are non-negotiable in healthcare settings. Tray systems must comply with strict health and safety regulations while allowing frequent upgrades.

Commercial and Office Spaces

In commercial buildings, aesthetics, flexibility, and ease of installation are important. Lightweight trays that blend with architectural elements are often preferred.

Installation Best Practices for Long-Term Performance

Proper Mounting Techniques

Correct mounting ensures stability and prevents undue stress on the tray and its supports. Whether ceiling-mounted, wall-mounted, or floor-supported, the method must match the structural capacity of the building.

Support Spacing Guidelines

Improper support spacing is one of the most common causes of tray sagging. Always follow the manufacturer’s recommendations to maintain load-bearing integrity.

Allowance for Thermal Expansion

Temperature changes cause materials to expand and contract. Proper allowances during installation prevent warping and joint failure.

Maintenance and Inspection of Raceway Cable Trays

Regular maintenance significantly extends the life of Raceway Cable Trays. Visual inspections help identify loose fasteners, corrosion spots, and physical damage early. Cleaning dust and debris prevents heat buildup and protects cable insulation. Any signs of bending, cracking, or coating failure should be addressed immediately to avoid system-wide issues.

Cost vs Quality in Selecting Top Raceway Cable Trays

Initial Purchase vs Lifetime Cost

While cheaper trays reduce upfront costs, they often lead to higher maintenance, frequent replacements, and unexpected downtime. High-quality trays offer lower lifetime costs.

Downtime and Business Impact

A failed tray system can bring down entire production lines or network systems. The financial impact of such downtime often far exceeds the cost of premium trays.

Return on Investment

Investing in Top Raceway Cable Trays improves reliability, reduces operational risk, and delivers strong returns over the life of the facility.

Common Mistakes to Avoid When Buying Raceway Cable Trays

Many buyers underestimate future cable loads, select materials unsuitable for their environment, or ignore expansion planning. These mistakes often result in premature replacements, safety hazards, and costly disruptions. A careful, forward-looking approach prevents these issues.

How to Choose the Right Manufacturer or Supplier

A reliable manufacturer should conduct thorough product testing, offer customization options, and provide strong technical support. Working with established suppliers like Super Cable Tray Pvt Ltd ensures access to quality engineering, tested products, and dependable after-sales service—three factors that significantly reduce project risk.

Real-World Examples of Cable Tray Selection

In a heavy manufacturing plant, ladder-type steel Raceway Cable Trays with corrosion-resistant coatings are often selected to handle thick power cables and harsh operating conditions. In contrast, a modern data center typically opts for wire mesh or aluminum trays to achieve maximum airflow and flexibility. These examples clearly show how tray selection varies based on application needs.

Modern Trends in Raceway Cable Tray Systems

Modular tray systems are gaining popularity for their flexibility and easy reconfiguration. Smart cable management solutions are also emerging, integrating sensors that monitor temperature and load conditions in real time. Additionally, sustainable manufacturing practices and recyclable materials are becoming standard in the industry as facilities push toward greener operations.

Final Checklist Before Purchasing Best Raceway Cable Trays

Before making your final decision, carefully verify load requirements, environmental compatibility, safety compliance, future expansion allowance, and manufacturer credibility. This simple evaluation process protects your investment and improves long-term performance.

Conclusion

Selecting high-quality Raceway Cable Trays is far more than a technical necessity—it is a strategic decision that impacts safety, efficiency, and business continuity. The right trays ensure organized cable routing, better airflow, reduced maintenance, and compliance with safety regulations. From material selection and load capacity to proper installation and maintenance, every detail plays a role in overall system reliability.

Facilities that prioritize quality over short-term savings experience fewer failures, lower downtime, and improved operational stability. Trusted manufacturers such as Super Cable Tray Pvt Ltd continue to lead the way by offering durable, compliant, and application-specific tray solutions. By choosing wisely today, you build a safer and more efficient infrastructure for years to come.